Specializes in making toilet seat cover mould,for both PP or UF material.

Specializes in making toilet seat cover mould,for both PP or UF material.

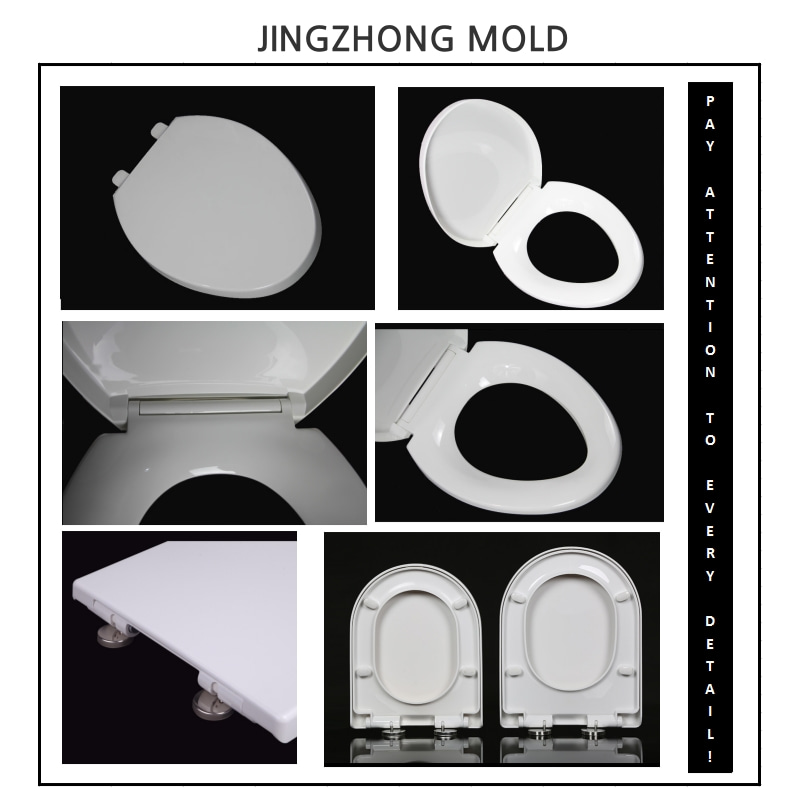

Product item: Urea-Formaldehyde Resins Toilet Seat Cover Mould

Toilet Seat Cover Mould can be single cavity or 2 cavities.It depends on the size of your machine. But for UF seat cover mold.It has to be one cavity.Cause it is using hydraulic press machine. Seat cover mold take up a great proportion in our company.Especially the Urea-Formaldehyde material.

Jingzhong Mold employs a team of quality control specialists, allowing us to test our custom-made products at the end of the production cycle and ensure quality in every Custom Plastic Component we build. No matter what your custom plastic piece will be used for, we test the design and implementation throughout the molding process, ensuring it will be of the highest quality.

Through our specialized OEM part testing and CAM equipment, creating Custom Molded Parts has never been more efficient. The design testing simulations integrated in our software helps ensure your custom-made thermoplastic component is of the highest possible standard.

We are located in Xiamen,China.Xiamen is a city which has many famous bathroom sanitary ware companies.We cooperate with many local factories and supply high quality Toilet Seat Cover Mold to them.Most of our local clients are selling seat cover to Euro and North America market. And since 2017,we start to delvelop overseas market by ourself.

Pls talk to us directly if need more information for the mold tooling.Our team of professional molders is dedicated to creating the very best OEM parts for you and your company and we can ensure you will have the finest custom plastic products at the lowest possible prices!

Product parameter:

Mold Base: LKM

Mold Service Life: 500,000 time

Mold Steel: NAK80/S136/as your request

Hot Runner: Depends on product

Production Process:

Packaging:

Company Information:

Xiamen Jingzhong Mold Co., Ltd. has many years of experience in the design and manufacture of rotary dampers. According to customer needs, we can produce all kinds of plastic injection molded parts and provide OEM services. Focus on quality control to ensure that the product is worth choosing!

FAQ:

Q: How long it will take for mold making?

A: Normally it will take about 35 days.But for toilet seat cover mold,it will take about 45 days.

Q: What's the mold service for mold?

A: More than 500,000 time.

Q: How to get a custom plastic product?

A: We can help to do product drawing if you can provide more detailed information.

Q: What's the package of the mold?Does it safe?

A: Pack by wooden case.It will be safe during the transit.

Request for Quotation

Request for Quotation