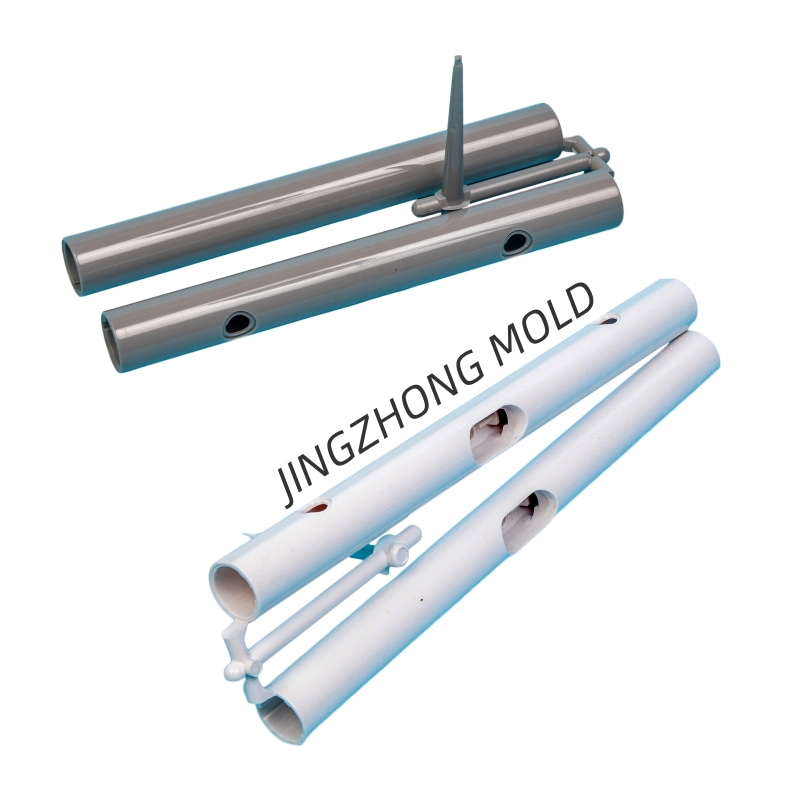

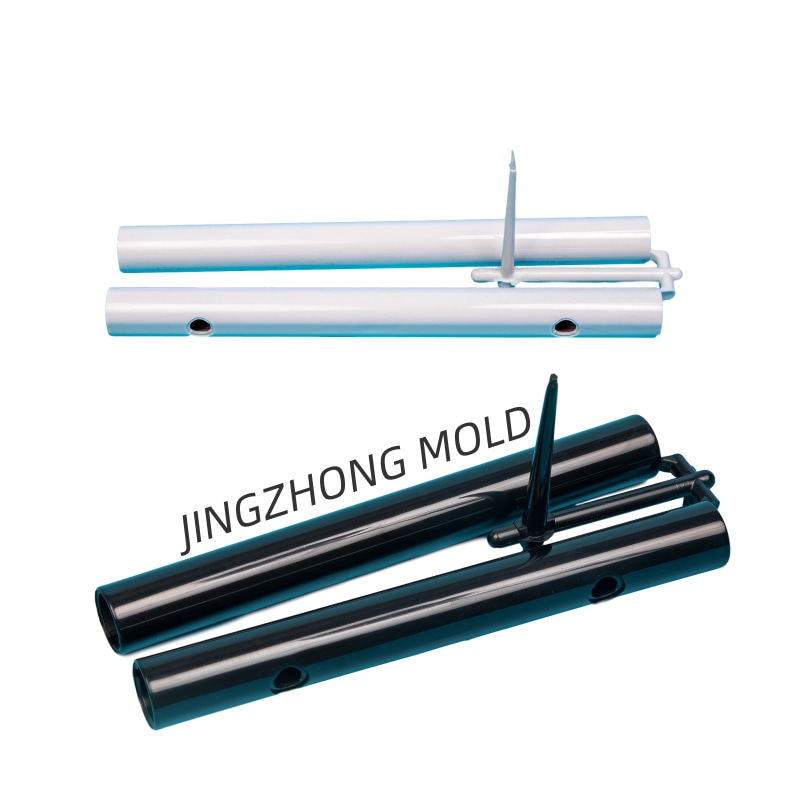

For custom plastic injection moulding tools,our work begins with tooling, or design a mold, for the plastic parts you need.

For custom plastic injection moulding tools,our work begins with tooling, or design a mold, for the plastic parts you need.

Product item: CustomThermoplastic Injection Moulding Tools

When it comes to consumer products, there are unlimited potential applications of Plastic Injection Molding. You’re only limited by your creativity, engineering tolerances, and market demand for your product. We can help you with the engineering and design to ensure a smooth manufacturing process.

We can use any kind of thermoplastic in the manufacturing process, but the most common choices include:

Acrylonitrile butadiene styrene, or

* ABS

* Polycarbonate

* Polyethylene

* High-impact Polystyrene

* Polypropylene

* Polymethylene

* PVC

* Nylon

* Acrylic

* Polyetherimide

Each compound has different strength and impact resistance levels. We’d be happy to advise you on the relative merits of different thermoplastics for your project or work with your product developers and/or engineers.

Product parameter:

Mold Base: LKM

Mold Service Life: 500,000 time

Mold Steel: NAK80/S136/as your request

Hot Runner: Depends on product

Packaging:

Company Information:

Xiamen Jingzhong Mold Co., Ltd. has many years of experience in the design and manufacture of rotary dampers. According to customer needs, we can produce all kinds of plastic injection molded parts and provide OEM services. Focus on quality control to ensure that the product is worth choosing!

FAQ:

Q: How long it will take for mold making?

A: Normally it will take about 35 days.But for toilet seat cover mold,it will take about 45 days.

Q: What's the mold service for mold?

A: More than 500,000 time.

Q: How to get a custom plastic product?

A: We can help to do product drawing if you can provide more detailed information.

Q: What's the package of the mold?Does it safe?

A: Pack by wooden case.It will be safe during the transit.

Request for Quotation

Request for Quotation