|

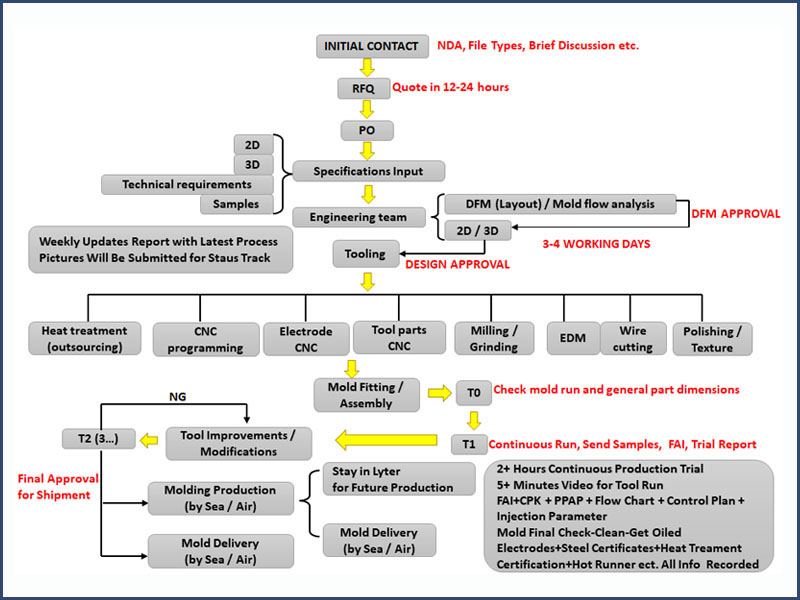

8. Tool Shipping (if required / overseas)

Sea and air freight options offered where the tool has been made for overseas customers. On tool arrival, our toolroom maintenance team will de-crate, strip clean and fully inspect the mould before it goes into a press for trial on site.

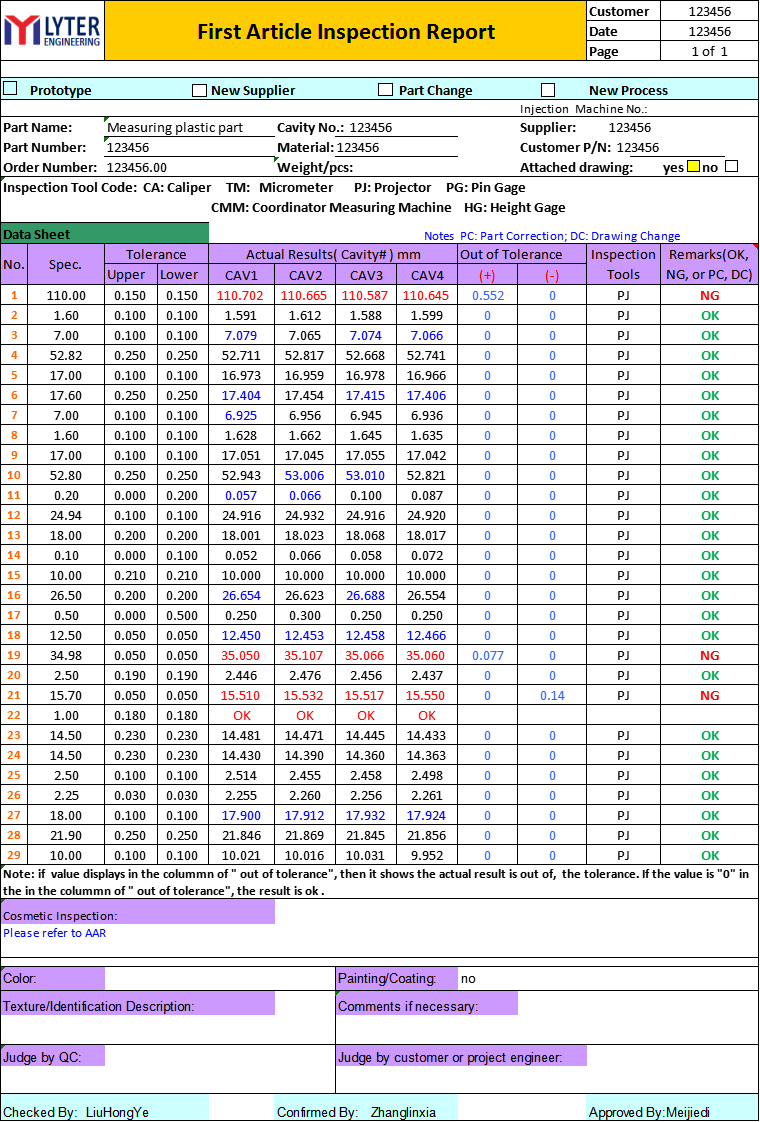

9. Approval & Sign off

From simple visual confirmation and sample approval sign off to full PPAP (Production Part Approval Process) style approval we will work with you to fully approve your part to the level you require.

At this stage the project is handed over to the production team for mass production.

Full capacity for dimension ISIR reporting.

Master retained samples held.

10. QA Specification

Part specific Quality plans produced for each part reflecting agreed quality levels at approval stage.

Part specific production dimensional and first off checks assigned for each part.

11. Production Handover

At handover from approval to production parts are controlled, scheduled and manufactured using the company wide ERP system.

Service contact assigned?

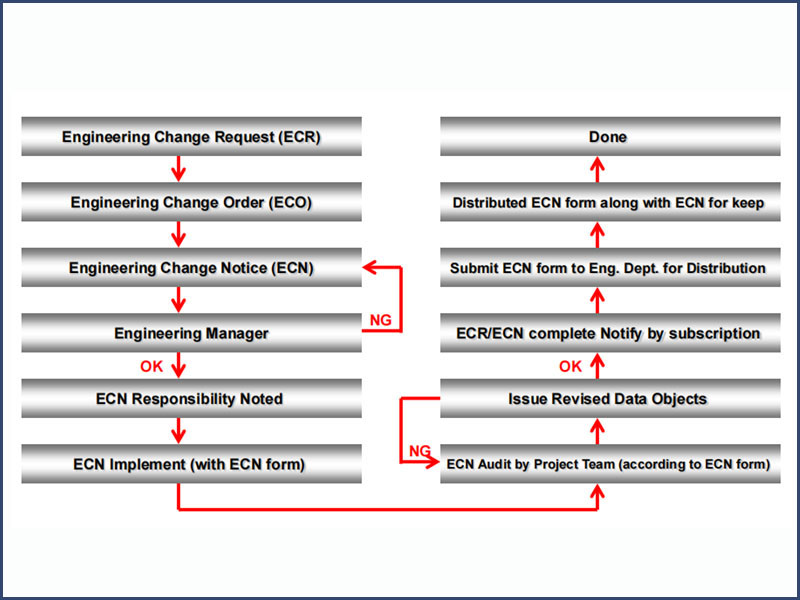

12. Continuous Improvement

We observe continuous improvement and best practices and will always look to advise of ways for streamlining work and reducing waste, cost and time.

13. To find out how we can help leave a message or book a call back

|

Request for Quotation

Request for Quotation