LYTER’s Tooling Design and Engineering team has over 16 years experiences in mold making industry.

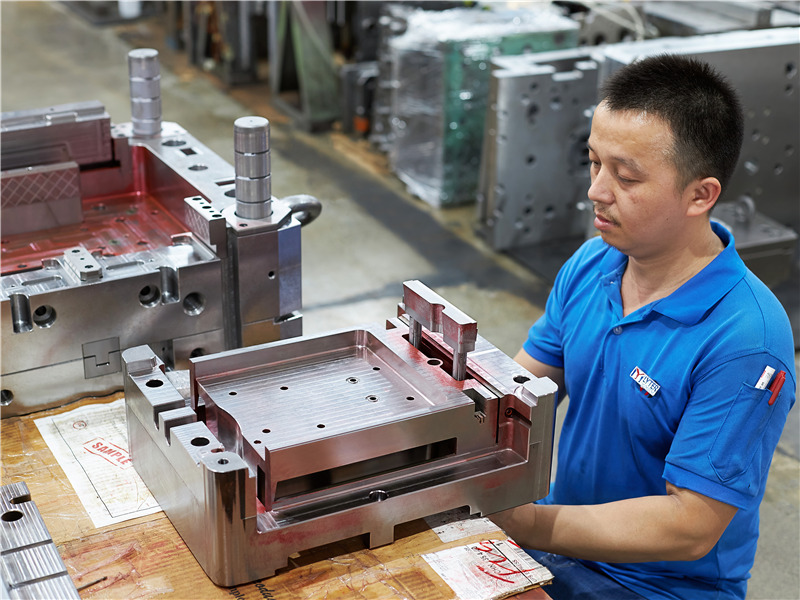

The team member includes experienced product and plastic injection mould design engineers, as well as mould making technicians with excellent craftsmanship.

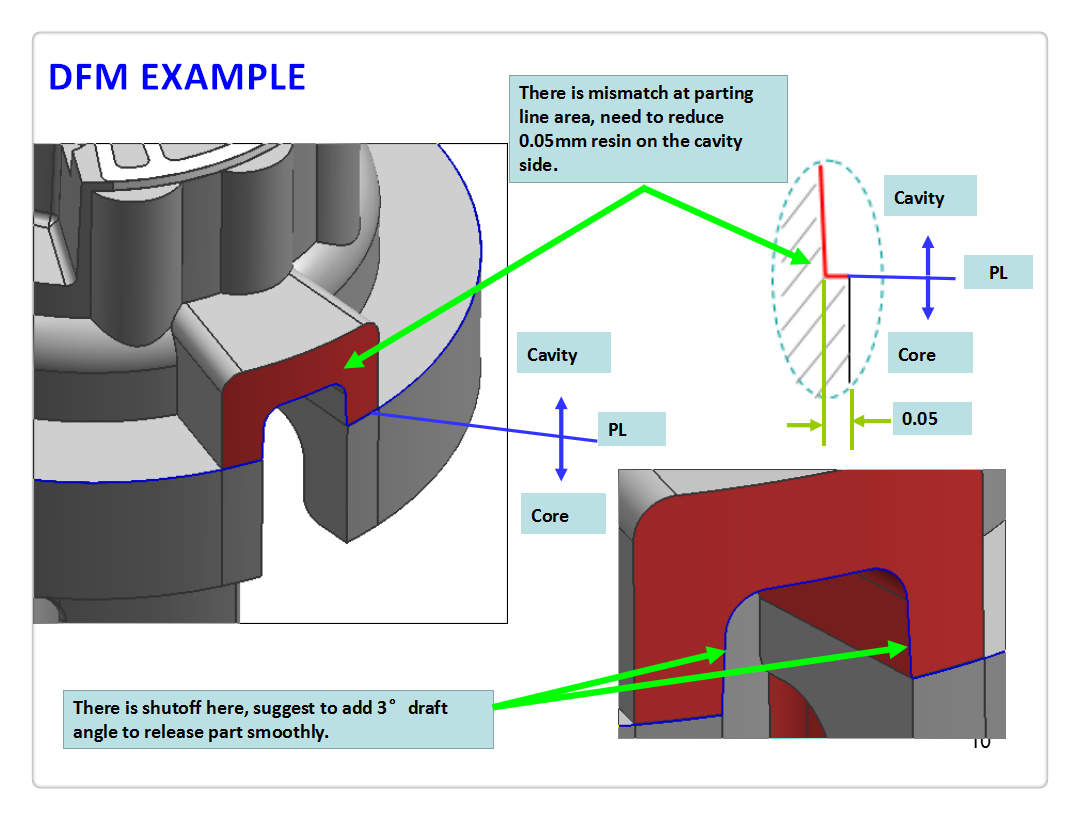

With years of tooling design and manufacturing and cooperation with reputational companies, such as GE, Whirlpool, Honda etc. from automotive and appliances industry, the company now has developed an effective management system to bring our values and expertise to meet customers satisfaction.

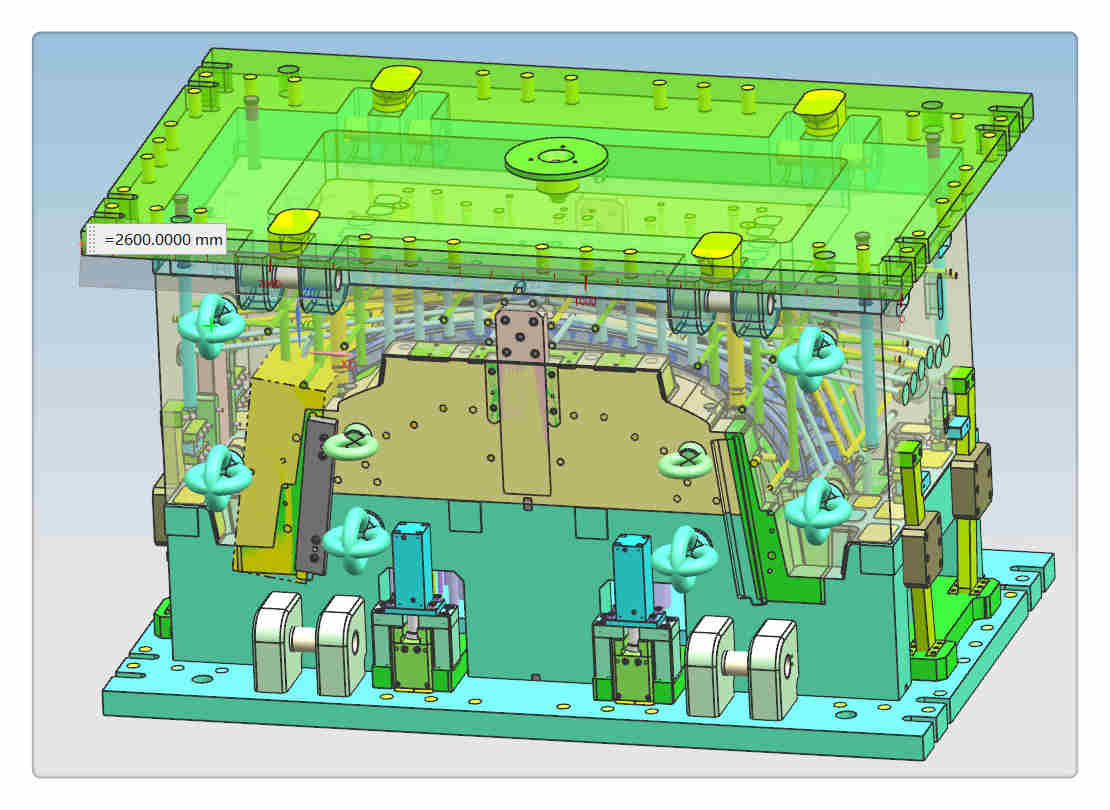

Our engineering department has 28 employees, include 22 engineers and 6 technicians, half of them has a good understanding of technical English, can read, write, listen and speak to customers fluently without language barrier. Our team has capacity to support your product design & development from very early stage to the production end.

Request for Quotation

Request for Quotation