In order to provide a one-stop solution to our customers, Lyter can offer some value-added solutions related to the plastic injection mould and moulding projects

through good relationship third parties. These services include Product Industrial and Mechanical Designs, Rapid Prototyping, Rapid Tooling, Global Shipment, Painting, etc.

|

|

|

|

|

|

Rapid Prototyping

Before making a mass production plastic injection moulds, you may would like to manufacture a prototype to test your part design. Lyter Engineering’s partner rapid prototype shop is equipped with 3D-Printing, SLA, CNC machines, and Prototype molding, which allows fast turnaround of prototype parts for our customers to test the assembly and appearance.

|

|

Industrial and Mechanical Design

If it is just a rough idea or a preliminary sketch, we can support to get you a completed and moldable product design, and bring it to the market in your target timing. After the design approval, we can then assist to make the prototypes to test, with the injection molding machines and die casting machines in house, we can also meet for mass production requests for some parts.

|

|

Global Shipment

We can offer door to door shipment service. It will be worry-free to work with us even if you don’t have much import experience. Our well trained and friendly employees can be really supportive. Good relationships with local forwarders, can handle air and sea freight smoothly and well tracked, world wide express like DHL, FedEx, UPS etc are also available.

|

|

|

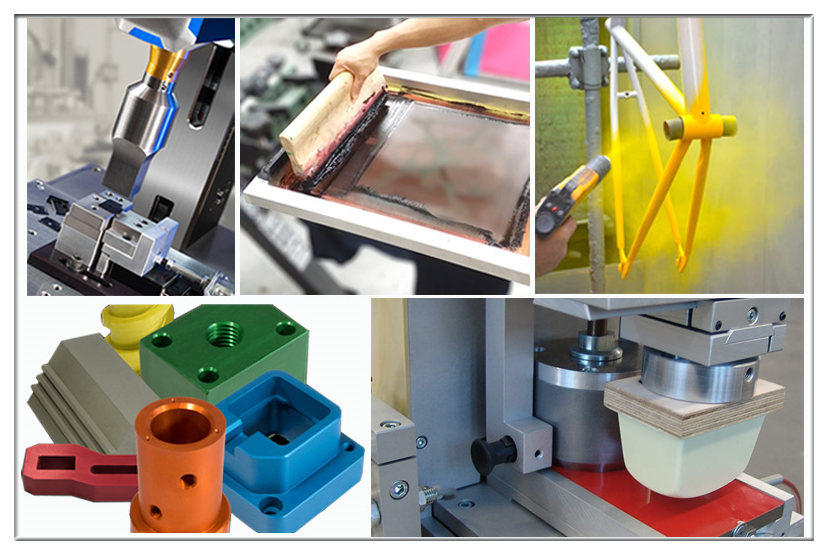

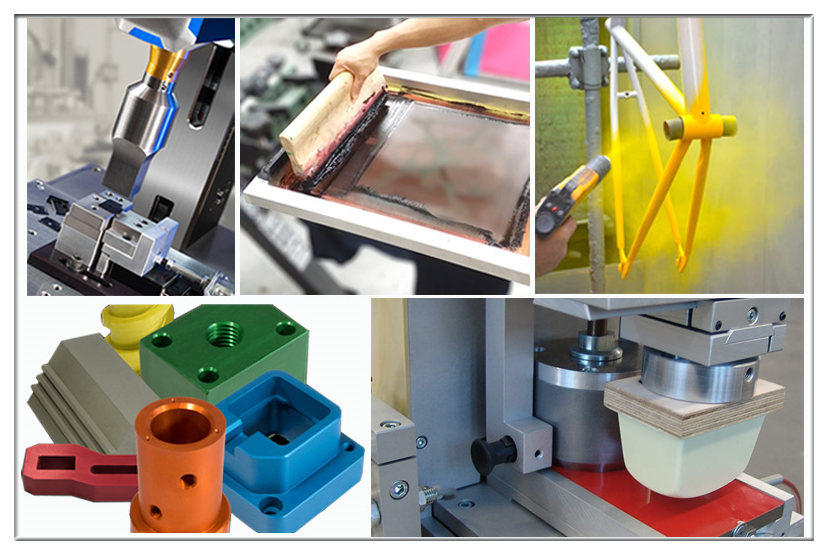

Secondary Processing

We can also provide secondary process including silk printing, pad printing, painting and electroplating etc. Secondary Processing Categories include Silk Printing, Pad printing, Heat transfer printing, Water transfer printing, Painting, Powder coating, Ultrasonic welding, Laser Etching, Anodizing, Electroplating.

Silk Printing

Silk printing is silk fabric synthetic, fiber fabric or metal mesh wireframe on the net frame using manual engraving plate-film or optical plate making method to produce a silk printing plate. Modern silk printing technology is using photosensitive materials to make silk printing plates by photographic plate (making silk printing screen holes instead of graphics parts screen holes blocked).

Printing through scraper extrusion makes ink transfer to the substrate through the mesh hole of the text section forming text similar to the original document. Silk printing equipment simple operation convenient printing plate easy to plate low-cost adaptability strong.

|

Silk printing applications are widely used in printed materials: color oil paintings posters, business cards, binding covers, commodity labels, printing textiles, etc.

Screen printing is not restricted by substrate size and shape, and it can use in different shapes and concave surfaces. A soft and flexible layout is one of the lowest printing pressure printing. Screen printing mode ink thick and strong adhesion. Only ink and paint can be used through a mesh diameter of mesh. It can print monochrome, also can color printing, and add screen color printing. It has strong light resistance, convenient plate making, low price, flexible printing style, diversified technology easy to grasp.

Painting

Painting is a kind of surface coating processing of industrial products. Generally, Painting processing is mainly engaged in plastic Painting, silk printing, and pad printing processing. It needs to meet the quality requirements of high temperature, friction, UV, alcohol, gasoline, and other test products.

Painting can make the monotonous product look more beautiful after spraying various colors, at the same time, it can also extend the service life and service life of the product due to more protection. It can solve the problems that the spray injection molding process encountered, such as flow lines, welding lines, with spray rubber oil (touch paint) experience, with touch paint rework technology.

Powder Coating

Electrostatic spraying of powder coating uses static electricity to adsorb the powder coating on the working surface. Besides, the powder is baked at high temperatures to form a solid coating on the working surface.

Electrostatic powder spraying firstly must have an electrostatic generator to produce DC high voltage, as well as a spray gun, a power supply system, and a powder recovery system to spray and atomize the powder. The sprayed workpiece should be grounded to a positive pole, while the negative high voltage generated in the discharge needle gun connected to the powder outlet of the spray gun will produce corona discharge through the discharge needle. At this time, the negatively charged powder particles arrive at the workpiece’s surface under the action of static electricity and compressed airflow.

Since the electrostatic force attraction, the powder is uniformly adsorbed on the workpiece surface for time without falling off, and the workpiece enters the curing furnace to flow flat and solidify, control the humidity or time, and finally form a tight, uniform, smooth and dense coating that binds firmly to the workpiece. Powder spraying makes the product surface smooth and has a coating with strong acid resistance, alkali resistance, crashworthiness, and wear resistance. And products can resist strong ultraviolet radiation and acid rain for a long time without coating pulverization, discoloration, shedding, and so on.

Anodizing

Anodizing divides into common anodizing and hard anodizing.

Metal anodizing is the process of forming a conversion film with wear and corrosion resistance, as well as other functional or decorative properties on the metal surface by electrochemical treatment in an electrolytic way. And the treated parts are the positive pole, while the corrosion-resistant material is the negative pole.

The objects of anodizing treatment can be aluminum and aluminum alloy, magnesium alloy, titanium and titanium alloy, etc. The anodizing of aluminum and aluminum alloy is a widely used and fast development in the market.

The main function of anodizing is to improve the hardness, wear resistance, corrosion resistance, and surface coloring of the workpiece, which plays a role in protecting and beautifying the workpiece surface.

Electroplating

Electroplating is using galvanolysis to plating other types of metals on the workpieces. It attaches parts surface to the metal film by electrolysis, and prevents metal oxidation (corrosion), improves abrasion resistance, conductivity, reflective resistance, corrosion resistance (copper sulfate) and beauty, etc.

Electroplated metal or other insoluble materials reduces the negative electrode of the positive electrode for the electroplated metal cation to form a coating on the workpiece surface. To eliminate interference from other cations and guarantee the plating uniform and firm, an electroplating solution should be applied for containing plating metal cations and keeping the same concentration of metal cations. Making the coating surface of the product consist of only the required coating metal to ensure the part quality.

Request for Quotation

Request for Quotation