Shunhao Machines & Moulds has more than 18 years experience in making uf toilet seat lid moulds.

Shunhao Machines & Moulds has more than 18 years experience in making uf toilet seat lid moulds.

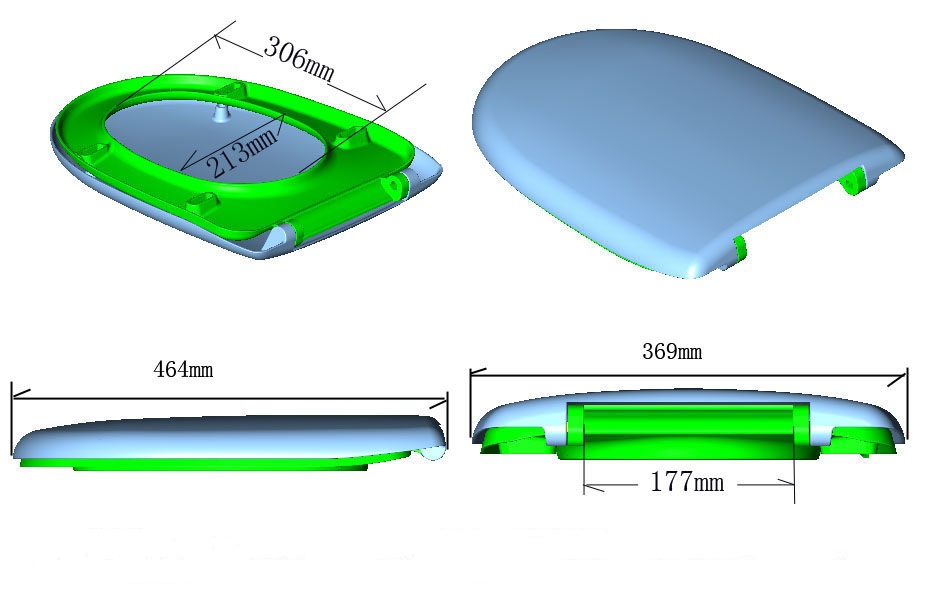

Urea Toilet Seat Cover Press Mould

Main Features

1. Accurate size, smooth surface, reasonable structure

2. Excellent production, quality assurance, reasonable price

3. Easy to manufacture, long life, low cost

4. High production efficiency, easy automation

5. According to different designs, different materials are made

Our Advantage

1. Shunhao Factory has more than 18 years experience in toilet lid moulds making.

2. Our factory uses high-quality plastic material and plastic mold material.

3. We have Custom's R&D team and skillful production team.

4. High precision CNC, EDM, Wire-cutting. Grinder, Milling for technical foundation.

Product Information

|

Mould type |

hot-press molding |

|

Mould material |

S136 |

|

Product material |

urea |

|

Number of cavities |

1 x 1 |

|

Product Description |

Use the toilet seat and cover mould to mold the raw material powder through high temperature and high pressure to get the finished product. The lid and seat separate, 2 pairs of mold |

|

Mould lifetime |

100,000 to 1,000,000 shots under normal use procedure |

|

Port |

XIAMEN |

|

Delivery Time |

By air or by sea, depends on your time. |

|

Supply ability |

30 sets per month |

Request for Quotation

Request for Quotation