Using two sets of hydraulic devices and separate operating boxes for the convenience of operation and maintenance.

Using two sets of hydraulic devices and separate operating boxes for the convenience of operation and maintenance.

Trainning Service :

YesSupport Service :

Life-time ServiceMachine Weight :

12000KGMachine Dimension :

2.6*1.5*3.2 M

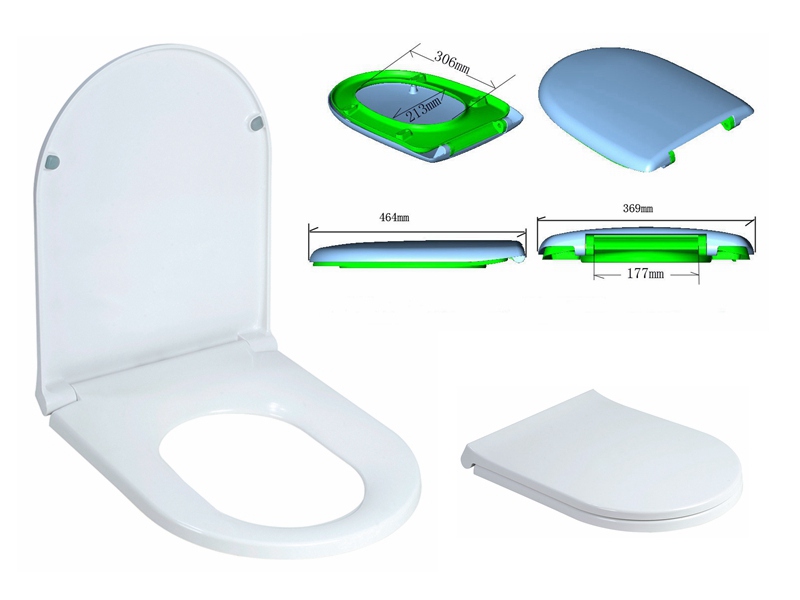

Single/Double Station UF/MF Toilet Seat Cover Molding Machine

Features

1. Simple operation, no noise, and automatic operation

2. Computer control uses Mitsubishi Electric and touch screen uses Fuji Electric, which is quite durable

3. Suitable for the forming operation of toilet seat cover (urea toilet seat cover)

Customization

1. The type of pressurized circulation system can be designed according to customer requirements.

2. The pumping speed and pressure can be set freely according to customer needs without restriction.

3. The mechanical function can be customized according to the customer's requirements so that the production has no worries.

4. It can be used for up-and-down heart-pulling action or heart-pulling in the mold, which can be tailor-made for customers.

Technical Parameters

|

No. |

Content |

DTB 600 |

|

1 |

Main Cylinder Nominal Pressure |

600Tons |

|

2 |

Maximum Working Pressure |

210kg/cm2 |

|

3 |

Main Cylinder Piston Diameter |

Ø600mm |

|

4 |

※Auxiliary Cylinder |

Shaft Ø50/pressure 12T |

|

5 |

Main Cylinder Working Stroke |

600mm |

|

6 |

Adjustable Table Distance |

600~900mm |

|

7 |

Heating Plate Size |

900*860mm |

|

8 |

Working Layers |

1 layer |

|

9 |

Heating Plate Material |

45# Special crafts |

|

10 |

Tension Column (Heat Treatment Grinding) |

Ø165*2692mm |

|

11 |

Oil Hydraulic Pump |

21Mpa |

|

12 |

Motor Specifications |

15HP |

|

13 |

Heating Sheet Total Power |

20.4KW |

|

14 |

Machine Total Power |

31.7KW |

|

15 |

Machine Size(length * width * height) |

2.6*1.5*3.2 M |

|

16 |

Machine Weight |

12000KGS |

■ PS: Specifications subject to change without notice.

Request for Quotation

Request for Quotation