Product Overview

|

Item

|

Description

|

|

Product Name

|

Frequency Inverter/ AC Drive

|

|

Model Number

|

V5/ V6-T-4Txx

|

|

Power Range

|

0.75kW-500kW

|

|

Rated Input Voltage

|

3 phase 380V/480V

|

|

Rated Output Voltage

|

3 phase 0 to rated input voltage

|

|

Input Frequency

|

50Hz/60Hz

|

|

Adaptable Motor

|

Asynchronous Motor

|

|

Control Mode

|

Tension Control, V/F Control, Vector Control, Sensorless Vector Control, Vector Torque Control, Sensor Vector Control

|

|

Communication

|

Modbus 485 RTU

|

|

IP Class

|

Standard IP20

|

|

Overload Capacity

|

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature)

|

Feature

■ Simple and reliable, cost-saving, easy to maintain on system, optional industry experience value, built-in control scheme, and wide range of applications

■ Diversified application of parameters, unified parameter setting, and intelligent parameter setting

■ Various tension schemes, anti-speed function, compensation on tension dynamic , built-in automatic roll change, tension taper function, roll diameter self-learning, PID adaptive function, no-encoder scheme, excellent vector performance

■ Remote debugging assistant ;and ;the system runs stably within two steps

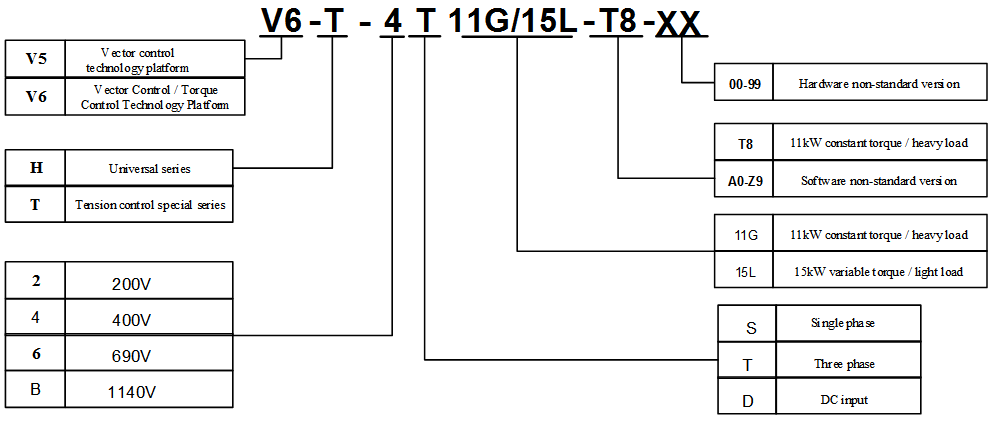

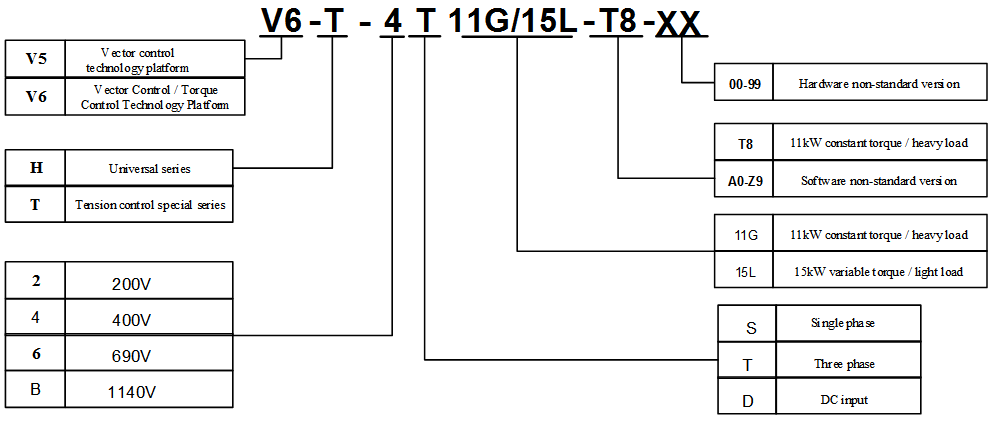

Model Explanation

Product Catalog

V6-T-4TXXX ; V5-T-4TXXX

|

Power (kW)

|

0.75

|

1.5

|

2.2

|

3.7

|

5.5

|

7.5

|

11

|

15

|

18.5

|

22

|

30

|

37

|

45

|

55

|

75

|

|

Motor

power (kW)

|

0.75

|

1.5

|

2.2

|

3.7

|

5.5

|

7.5

|

11

|

15

|

18.5

|

22

|

30

|

37

|

45

|

55

|

75

|

|

Output

|

Voltage (V)

|

Three-phase 0 to rated input voltage

|

|

Rated current (A)

|

2.5

|

3.8

|

5.5

|

9

|

13

|

17

|

24

|

30

|

39

|

45

|

60

|

75

|

91

|

112

|

150

|

|

Overload

capacity

|

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag

feature)

|

|

Input

|

Rated

voltage/frequency

|

Three-phase 380V/480V; 50Hz/60Hz

|

|

Allowable voltage

range

|

323V ~ 528V; Voltage imbalance ≤3%; allowable frequency fluctuation: ±5%

|

|

Rated current (A)

|

2.8

|

4.2

|

6.1

|

10

|

15

|

19

|

26

|

33

|

43

|

50

|

66

|

83

|

100

|

123

|

165

|

|

Braking unit

|

Built-in as standard

|

Built-in as option

|

|

Protection class

|

IP20

|

|

Cooling mode

|

Natural−cooling

|

Forced air cooling

|

|

Power (kW)

|

90

|

110

|

132

|

160

|

185

|

200

|

220

|

250

|

280

|

315

|

355

|

400

|

450

|

500

|

|

|

Motor

power (kW)

|

90

|

110

|

132

|

160

|

185

|

200

|

220

|

250

|

280

|

315

|

355

|

400

|

450

|

500

|

|

|

Output

|

Voltage (V)

|

Three-phase 0 to rated input voltage

|

|

Rated current (A)

|

176

|

210

|

253

|

304

|

350

|

380

|

426

|

470

|

520

|

600

|

650

|

690

|

775

|

860

|

|

|

Overload

capacity

|

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag

feature)

|

|

Input

|

Rated

voltage/frequency

|

Three-phase 380V/480V; 50Hz/60Hz

|

|

Allowable voltage

range

|

323V ~ 528V; Voltage imbalance ≤3%; allowable frequency fluctuation: ±5%

|

|

Rated current (A)

|

160*

|

196*

|

232*

|

282*

|

326*

|

352*

|

385*

|

437*

|

491*

|

580*

|

624*

|

670*

|

755*

|

840*

|

|

|

Braking unit

|

External braking unit needed

|

|

Protection class

|

IP20

|

|

Cooling mode

|

Forced air ;cooling

|

Technical Parameters

|

control method

|

High performance vector control tension control

|

|

Power range

|

0.75kW~500 kW

|

|

Input voltage, frequency

|

3AC 380V~480V;50Hz/60Hz

|

|

Input voltage, frequency

|

3AC 0 ~ rated input voltage

|

|

Output frequency

|

0.0~300.0Hz

|

|

Digital input and output

|

Standard multi-function input terminal, expandable

Standard open collector output, expandable

|

|

Analog input and output

|

Input: AI1 0~20 mA, input impedance 500Ω, maximum input current 30mA;

0 to 10V, input impedance 20kΩ,

Maximum input voltage 15V, resolution is 12 bits (0.025%)

Select 0 to 20 mA or 0 to 10V analog input by jumper

;

AI2 Same as above

AI3 −10V~10V, input impedance 20kΩ maximum input voltage ±15V, resolution 12 bits (0.025%)

Output: AO1 0~20 mA, output allowable impedance 200~500Ω

0 to 10V, output allowable impedance ≥10kΩ, resolution is 10 bits (0.1%)

Short-circuit protection function, select 0~20 mA or 0~10V analog output by jumper

;

AO2 Same as above

|

|

Pulse input and output

|

Pulse input: 0.1Hz ~ 50kHz; voltage range: 24V ± 20%

Pulse output: 0 ~ 50kHz; voltage range: 24V ± 20%

|

|

Protocol

|

Dual 485 communication interface supports Modbus protocol (RTU), standard operation panel can realize remote control, up to 500 meters

|

|

Brake unit

|

15kW and ;lower ;power ;grades ;are built-in;

18.5kW ~ 75kW power ;grades are ;built-in ;as ;option;

90kW and ;higher ;power ;grades ;need to be external;

|

|

External interface

|

DC24V power supply, maximum output current 100 mA

|

|

DC reactor

|

90kW and ;higher ;power ;grades ;models ;are ;standard with external DC reactor

|

|

Installation method

|

Wall mounting

|

|

Protection level

|

IP20

|

Model table

|

Voltage

|

Model

|

Single/three phase 200V constant torque / heavy duty application

|

|

;Motor (kW)

|

Rated output current (A)

|

Rated input current (A)

|

|

400V

|

V5/V6−T−4T0.75

|

0.75

|

2.5

|

2.8

|

1.5

|

3.3

|

3.6

|

|

V5/V6−T−4T1.5

|

1.5

|

3.8

|

4.2

|

2.2

|

5.0

|

5.5

|

|

V5/V6−T−4T2.2

|

2.2

|

5.5

|

6.1

|

3.7

|

7.5

|

8.3

|

|

V5/V6−T−4T3.7

|

3.7

|

9

|

10

|

5.5

|

11

|

12

|

|

V5/V6−T−4T5.5

|

5.5

|

13

|

15

|

7.5

|

17

|

19

|

|

V5/V6−T−4T7.5

|

7.5

|

17

|

19

|

11

|

22

|

25

|

|

V5/V6−T−4T11

|

11

|

24

|

26

|

15

|

30

|

33

|

|

V5/V6−T−4T15

|

15

|

30

|

33

|

18.5

|

37

|

40

|

|

V5/V6−T−4T18.5A*

|

18.5

|

39

|

43

|

22

|

44

|

50

|

|

V5/V6−T−4T22A

|

22

|

45

|

53

|

30

|

56

|

62

|

|

V5/V6−T−4T30A

|

30

|

60

|

66

|

37

|

72

|

80

|

|

V5/V6−T−4T37A

|

37

|

75

|

83

|

45

|

91

|

100

|

|

V5/V6−T−4T45A

|

45

|

91

|

100

|

55

|

110

|

121

|

|

V5/V6−T−4T55A

|

55

|

112

|

123

|

75

|

142

|

156

|

|

V5/V6−T−4T75A

|

75

|

150

|

165

|

90

|

176

|

194

|

|

V5/V6−T−4T90

|

90

|

176

|

160

|

110

|

210

|

196

|

|

V5/V6−T−4T110

|

110

|

210

|

196

|

132

|

253

|

232

|

|

V5/V6−T−4T132

|

132

|

253

|

232

|

160

|

304

|

282

|

|

V5/V6−T−4T160

|

160

|

304

|

282

|

185

|

350

|

326

|

|

V5/V6−T−4T185

|

185

|

350

|

326

|

200

|

380

|

352

|

|

V5/V6−T−4T200

|

200

|

380

|

352

|

220

|

426

|

385

|

|

V5/V6−T−4T220

|

220

|

426

|

385

|

250

|

470

|

437

|

|

V5/V6−T−4T250

|

250

|

470

|

437

|

280

|

520

|

491

|

|

V5/V6−T−4T280

|

280

|

520

|

491

|

315

|

600

|

580

|

|

V5/V6−T−4T315

|

315

|

600

|

580

|

355

|

650

|

624

|

|

V5/V6−T−4T355

|

355

|

650

|

624

|

400

|

690

|

670

|

|

V5/V6−T−4T400

|

400

|

690

|

670

|

450

|

775

|

755

|

|

V5/V6−T−4T450

|

450

|

775

|

755

|

500

|

860

|

840

|

|

V5/V6−T−4T500

|

500

|

860

|

840

|

450

|

950

|

920

|

In this table, “A” indicates the structure version, and the default is the original version, which is A, B······.

Installation Dimensions

V5/V6−T−4T7.5 and below ;power class ;

V5/V6−T−4T11 and ;above ;power ;class

|

Voltage

|

Model

|

Appearance ;and installation dimensions (mm)

|

;weight (kg)

|

|

W

|

H

|

D

|

W1

|

H1

|

D1

|

T1

|

Hole d

|

|

400V

|

V5/V6−T−4T0.75

|

118

|

190

|

155

|

105

|

173

|

40.8

|

3

|

5.5

|

1.5

|

|

V5/V6−T−4T1.5

|

118

|

190

|

175

|

105

|

173

|

60.5

|

4

|

5.5

|

2.6

|

|

V5/V6−T−4T2.2

|

|

V5/V6−T−4T3.7

|

|

V5/V6−T−4T5.5

|

155

|

249

|

185

|

136

|

232

|

69

|

8

|

5.5

|

; ;3

|

|

V5/V6−T−4T7.5

|

|

V5/V6−T−4T11

|

210

|

337

|

200

|

150

|

324

|

107.5

|

2.5

|

7

|

8.5

|

|

V5/V6−T−4T15

|

|

V5/V6−T−4T18.5A*

|

285

|

440

|

220

|

200

|

425

|

107.5

|

2.5

|

7

|

17

|

|

V5/V6−T−4T22A

|

|

V5/V6−T−4T30A

|

|

V5/V6−T−4T37A

|

315

|

575

|

227

|

220

|

553

|

123.5

|

2.5

|

10

|

25

|

|

V5/V6−T−4T45A

|

|

V5/V6−T−4T55A

|

400

|

615

|

265

|

270

|

590

|

123.5

|

3.0

|

10

|

35

|

|

V5/V6−T−4T75A

|

|

V5/V6−T−4T90

|

465

|

745

|

325

|

343

|

715

|

156

|

3.0

|

12

|

55

|

|

V5/V6−T−4T110

|

|

V5/V6−T−4T132

|

540

|

890

|

385

|

370

|

855

|

205.5

|

4.0

|

14

|

85

|

|

V5/V6−T−4T160

|

|

V5/V6−T−4T185

|

|

V5/V6−T−4T200

|

|

V5/V6−T−4T220

|

700

|

1010

|

385

|

520

|

977

|

210

|

4.0

|

14

|

125

|

|

V5/V6−T−4T250

|

|

V5/V6−T−4T280

|

|

V5/V6−T−4T315

|

810

|

1358

|

425

|

520

|

1300

|

210

|

4.0

|

14

|

215

|

|

V5/V6−T−4T355

|

|

V5/V6−T−4T400

|

810

|

1358

|

425

|

520

|

1300

|

210

|

4.0

|

14

|

215

|

|

V5/V6−T−4T450

|

|

V5/V6−T−4T500

|

Option / Expansion Card

|

category

|

Name

|

Model

|

Function Explanation

|

Refer

|

|

Operation panel

|

Operation panel (shuttle ;type)

|

V6−DP01

|

Standard models of 7.5kW and below

|

P2−**

|

|

Operation panel (button type)

|

V6−DP02

|

11kW and above models are standard

|

P2−**

|

|

Text display

|

EX−MT01

|

Man-machine interface - text display

|

P2−**

|

|

touch screen

|

EX−MT02

|

Human-machine interface - touch screen

|

P2−**

|

|

Fake panel

|

V6−DP03

|

Customer option

|

P2−**

|

|

Pallet

|

V6−DP05

|

Operation panel mounting accessories

|

P2−**

|

|

Expansion Card

|

Power monitor card

|

EX−PA01

|

Three-phase input power supply phase loss / instantaneous power failure monitoring

|

P2−**

|

|

Phase-sequence detection card

|

EX−PA02

|

Three-phase input power phase detection

|

P2−**

|

|

Speed tracking card

|

EX−PA03

|

Speed tracking

|

P2−**

|

|

External ;power rectification card

|

EX−RF01

|

Control power is provided by external power supply

|

P2−**

|

|

Programmable ;CAN ;bus extension card

|

EX−CA05

|

;

|

P2−**

|

|

Profibus ;DP ;communication card

|

EX−CA06

|

;

|

P2−**

|

|

Keyboard extension cord

|

2 m keyboard extension cord

|

CB1−200

|

;

|

P2−**

|

|

3 ;m keyboard extension cord

|

CB1−300

|

;

|

P2−**

|

|

Base

|

Inverter base

|

;

|

Optional for 90kW and above power models

|

;

|

|

PG ;card(V6−T ;for option)

|

PG ;feedback card ;(12V)

|

EX−PG01

|

A/B/Z open collector/differential/push-pull

|

P2−**

|

|

PG ;feedback card ;(5V)

|

EX−PG02

|

A/B/Z open collector/differential/push-pull

|

P2−**

|

|

PG ;feedback ;with frequency dividing output (12V)

|

EX−PG03

|

12V−PG feedback cassette with crossover output

|

P2−**

|

|

PG ;feedback ;with frequency dividing output (5V)

|

EX−PG04

|

5V−PG feedback cassette with crossover output

|

P2−**

|

|

PG ;Feedback card for UVW code disk

|

EX−PG06

|

Feedback card for UVW code disk

|

P2−**

|

|

PG ;Feedback ;card/rotary transformer

|

EX−PG07

|

Feedback card for resolver

|

P2−**

|

Applications

Representative Industry

Speed control application that there is a roll diameter calculation and tension with pendulum but no encoder. such as warping machine, sizing machine, dyeing machine, non-woven slitting machine, winding machine, laminating machine, coating Machine, laminating machine, laminating machine, bag cutting machine, single frequency conversion, double frequency conversion, straight wire drawing machine, cable machine, paper machine, slitting machine, surface reeling machine, rewinding machine, gravure printing machine, Flexographic printing machines, dyeing machines, dyeing machines, metal processing cold-rolling machines, hot-rolling machines, layer winding machines, winding machines, unwinding frames, leather winders, extruders, etc. In addition,the Shenzhen V&T Technologies Co.,Ltd. V6−T can be used as an replacement torque motor with torque control and constant tension control and it can also be used as replacing magnetic powder clutch.

Request for Quotation

Request for Quotation