Professional Introduction for Melamine Crockery Moulds

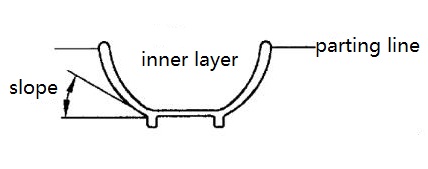

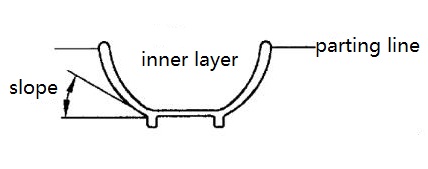

1. Parting line

The parting line is parallel to the working plate of the melamine crockery molding machine. After the mold is opened, it is divided into upper mold and lower mold. We normally call them male mold (Male cavity / Punch) and female mold (Female cavity/ Cavity), which is used for air exhausting, decal paper, demolding, as well as mold processing.

2. Mold structure

-

If the melamine tableware is deeper or straight, the more difficult for the product molding or releasing from mold because it is easier to get stuck in the upper or lower mold.

-

Forcibly releasing the melamine product will cause breakage or shortage of powder, the rejects is more and lower production efficiency.

-

Therefore, when designing the mold, the mold factory designers will make accurate predictions on the shape and height of the special product, to avoid any unreasonable design, and make sure that the melamine products can release from the molds easily with proper height and slope.

3. Double color melamine mold

-

In the production of 2 color melamine tableware, the flash of the base must not be broken before 2nd time molding to avoid the edge scraps of the base layer and the white material in the inner layer from spreading outside the base.

-

To achieve this, must operate carefully and pay attention to the structure of the mold: the general product slope is less than 70°, the surface roughness of the mold cavity is lower than Ra 0.4 or less, and between the male and female molds need the exhaust gap 0.1mm, the male angle of the molding slope needs to be larger than the female mold by 1°~2°, and the blank holder width is more than 6mm.

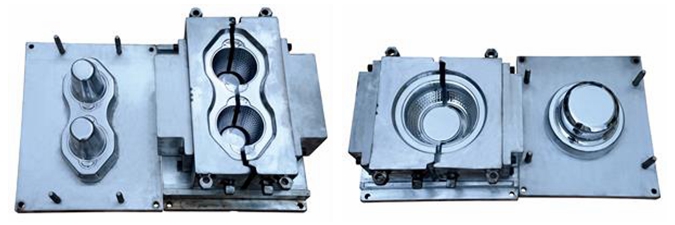

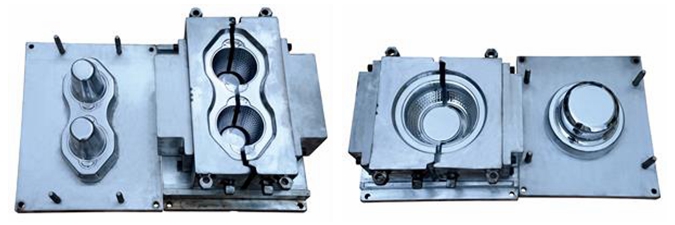

(Picture of split mold)

-

Melamine pressing molds are divided into single-color molds and double-color molds. In recent years, melamine molds for various S-shaped products have also emerged in the past two years. Professionally called SPLIT MOLDS. The split mold is designed for S-shaped products.

-

In addition to opening and closing the mold, it can also open and close from the left and right horizontally, eliminating the limitations of the melamine mold industry on product modeling, thus developing various new or clear lines of new melamine products which are favored by many melamine tableware factories, like Ice cream cup, salty box, etc.

Shunhao Spilt Moulds

1. Hard chrome plating, more glossy finished melamine items

2. Well-designed molds structure, easy running in tableware factory

3. Qualified steel materials, Value for each dollar of tableware factory

4. Well tested strictly quality control before molds shipment

5. Experienced designers team, nature stone or wooden texture molds

6. Top brand CNC running in Shunhao factory in 2020

7. On time delivery and exporting seaworthy packing

If you have the new molds to make, welcome to send the inquiry to Shunhao Company.

Request for Quotation

Request for Quotation