We supply Excellent quality Nano White Calacatta Glass Marble Slabs for interior and exterior application. Many colors and patterns are available in stock for fast delivery. Wholesales competitive price.

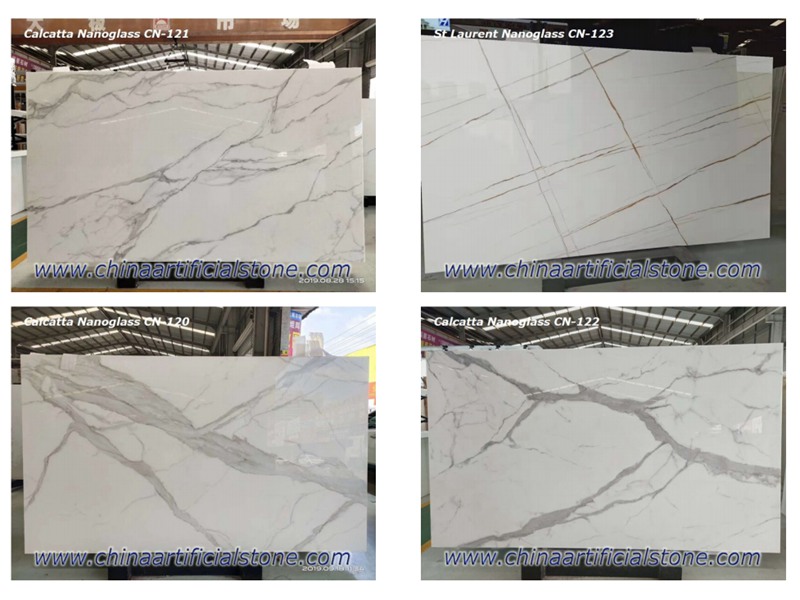

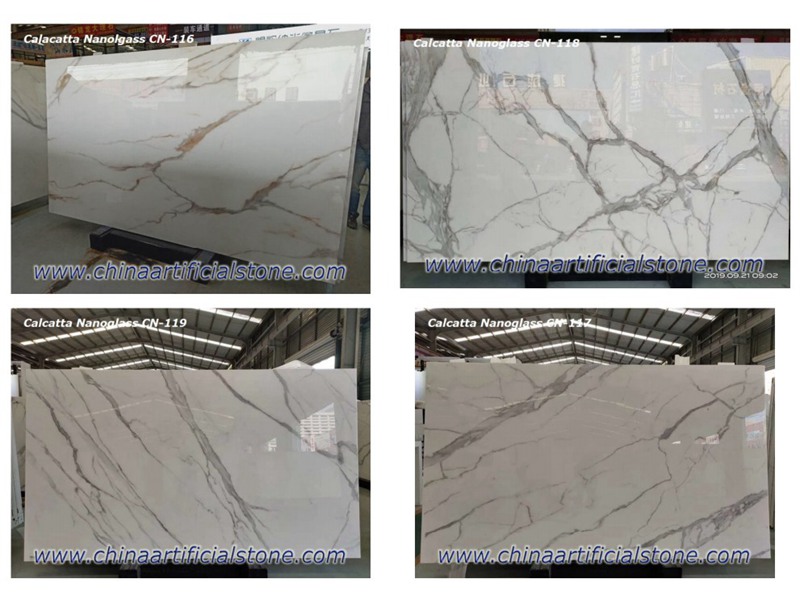

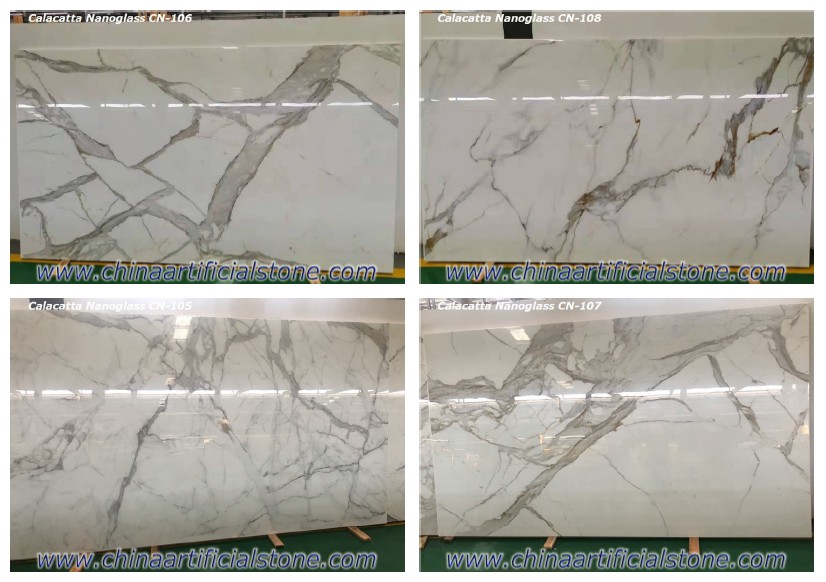

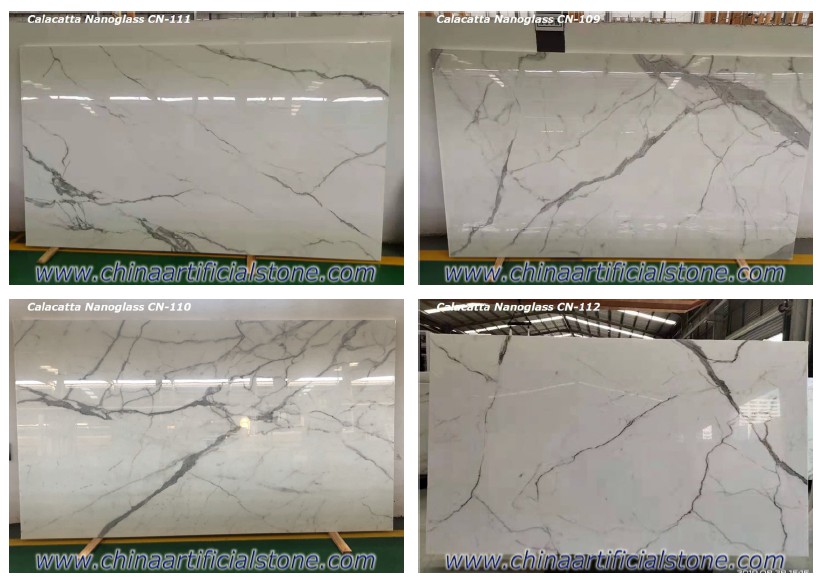

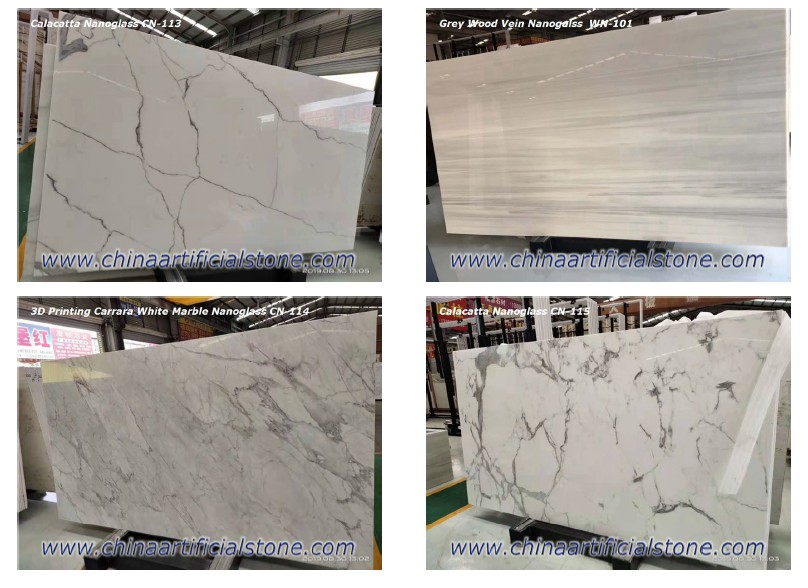

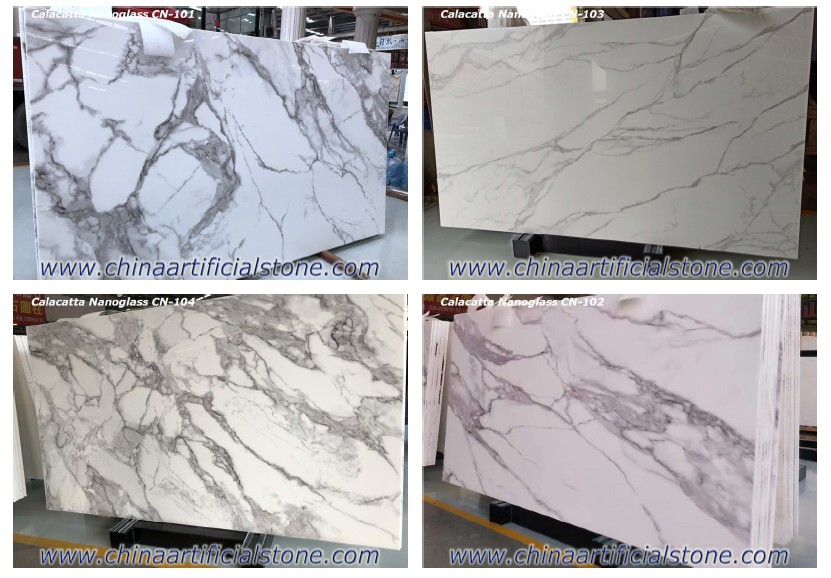

Color Code: CN-101-CN115, 15 patterns available by far, more are coming out soon.

Slab Size: 2800x1600mm, 2800x1500mm, real slab size 6cm more by length and 4cm more by height.

Thickness: 18mm normally, 10mm and 30mm are also workable if order quantity up to 5000m2

FOB Port: Jiujiang or Xiamen

Packing: Strong Fumigated Wooden Bundles. 15-16pcs./Bundles

Loading: 20GP=120pcs. 2800x1600x18mm=128pcs. 2800x1500x18mm=26880kgs

Application: Indoor or outdoor Countertops, Table Tops, Bench tops, Work tops, floor and wall facade tiles, Columns.

Nano White Calacatta Glass Marble Slab is an artificial stone with grey or gold marble pattern look Nanoglass Stone. The marble veins patterns are printed by 3D Printing technology base on premium quality pure white Nanoglass slabs. after been reheating, the veins colors are strong absorbed in the slabs, that makes the pattern more natural looking. It is a strong and hard, without any grain on background, the vein color will not be fade, zero water absorption.

We can fabricate seamless book matched Mitered edge Calacatta Nano Glass Countertops.

The advantage of the Nanoglass:

1 Avoid the problems of easy breakage in cutting.

2 Harder in texture and better in quality than natural stone.

3 More pure white in color,no color difference in large quantities

4 No chip, crack and breakage in the processing.

5.Water absorption is 0% ,no water,oil,blot absorption(easy cleaning).

6.No radioactivity.

7.Stain resistance high gloss.

8.High consistence,good strength.

Appliaction of the Nanoglass

Floor tile, Wall cladding, Kitchen countertop, Vanity top, Table top, Dinning table top, Cabinet top, Laundry top, Furn Apartment&villa, 5 star Hotel,Train statoion,airport,Shopping Mall,KTV,Office

More 3D Printing Nanoglass Slab patterns as bellow:

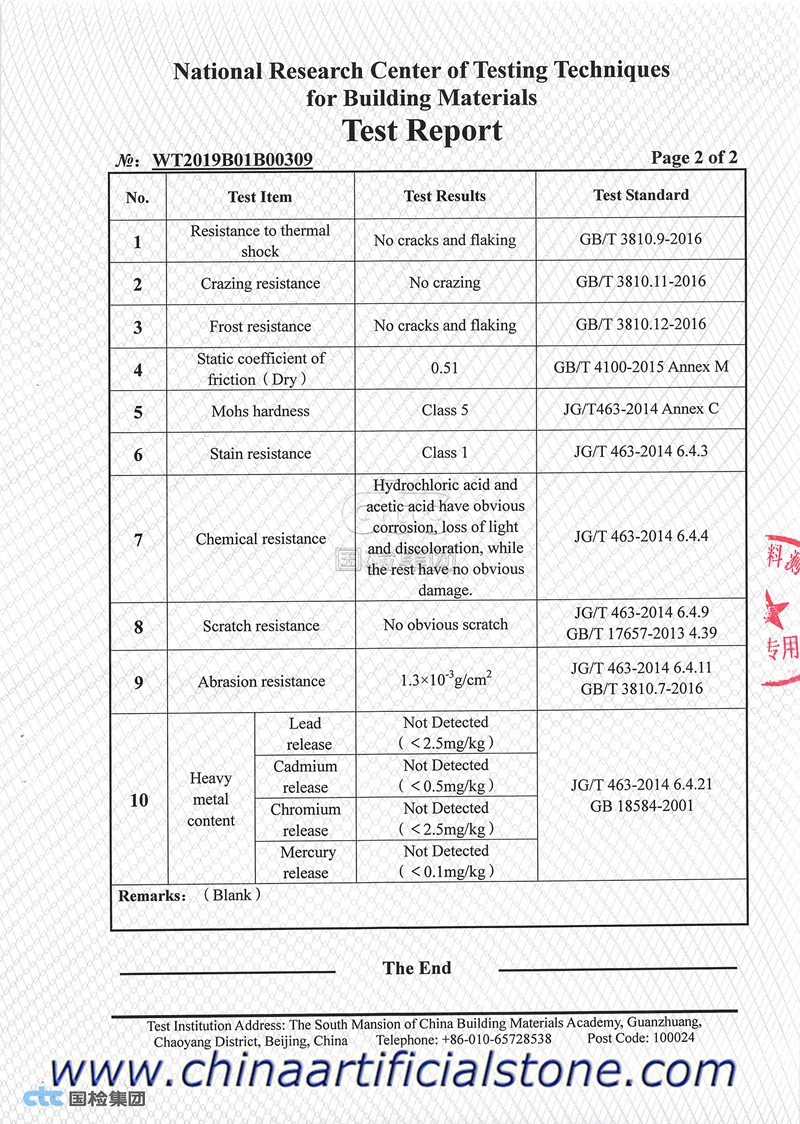

Inject Printing Nano Crystallized Glass Stone test report on March 2019

Request for Quotation

Request for Quotation