HouYuan Pass Through Double Door Autoclave

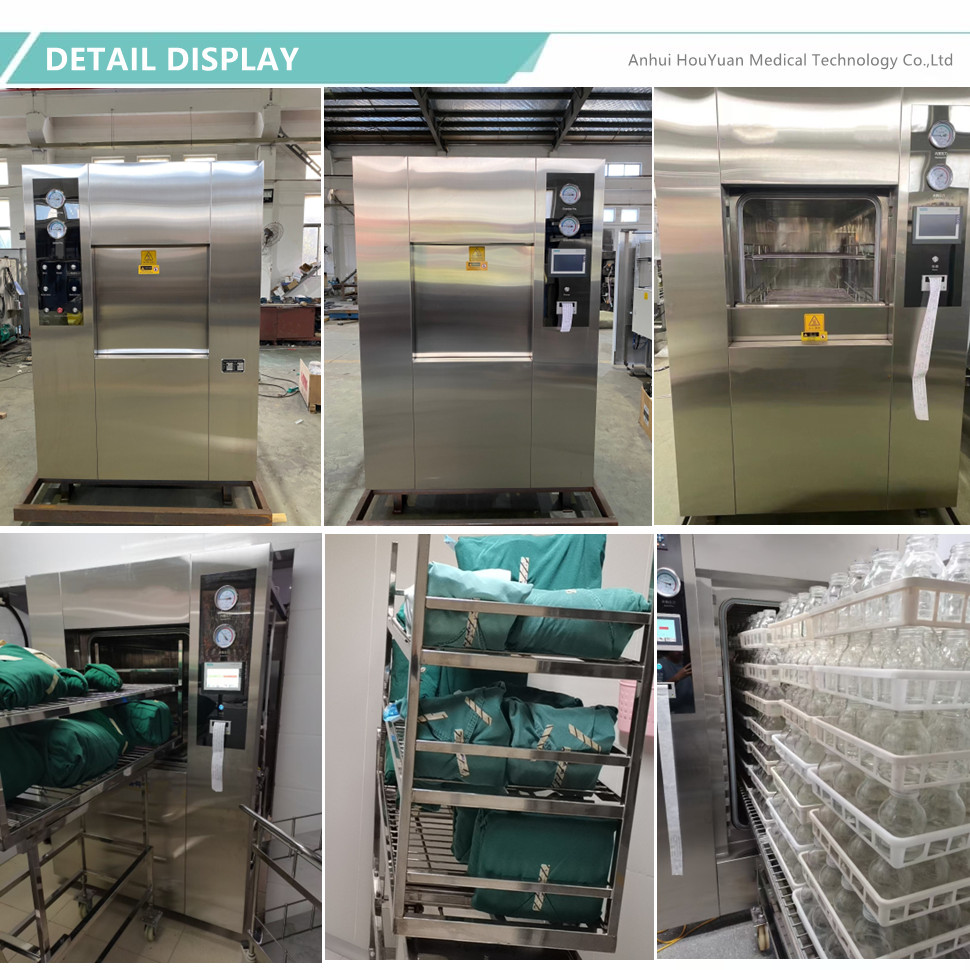

The HY-JS series autoclave uses saturated steam as the sterilization medium, and the physical characteristics of releasing a large amount of latent heat and humidity when saturated steam condenses, so that the items to be sterilized are in a high temperature and humid state. Keep warm for a period of time to achieve the purpose of sterilization. Pulsating vacuum exhaust is used to eliminate the influence of cold air on temperature, and finally vacuum dehumidification is combined with jackets to dry the sterilized items.

Mainly used in hospital disinfection supply rooms, third-party disinfection supply centers, operating rooms, laboratories, etc., to sterilize medical devices, dressings, rubber, luminal devices, implantable devices, liquids, etc.

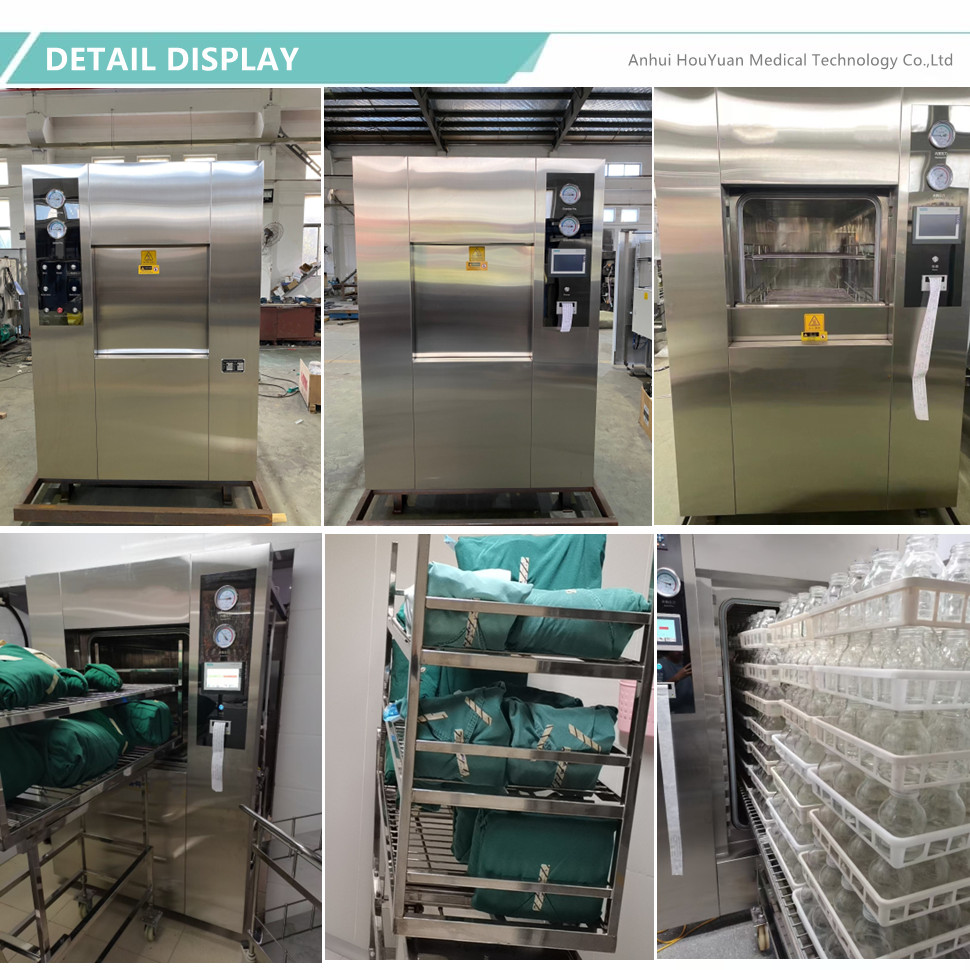

Main body:

* The main structure is a rectangular cross-section with a European-style ring-shaped stiffener jacket structure.

* The door sealing method is pneumatically sealed, and the double door interlocking fully meets the specification requirements.

* The inner tank, door panel and other materials in contact with steam are all high-quality SUS304 stainless steel, with a design life of up to 10 years and 20,000 sterilization cycles.

* Optional SUS316 stainless steel, design life up to 15 years, 30,000 sterilization cycles;

* The front teeth and the main retaining teeth are made of SUS304 stainless steel, and the jacket is made of high-quality Q245R special materials for pressure vessels (SUS304 is optional);

* With standard GMP verification interface;

Piping system:

* 304 stainless steel sanitary pipeline, clamp type connection;

* Imported German GEMU angle seat pneumatic valve, Taiwan Airtac solenoid valve and imported German SPECK direct connection water ring vacuum pump;

* Optional: Intelligent automatic drainage system, water saving and noise reduction system and pipeline insulation treatment;

Control System:

* Imported Siemens programmable controller PLC and color touch screen on the operating side;

* The printer prints the process data of each stage in real time;

* Various security and alarm systems;

* With a communication interface connected to the quality traceability system of the disinfection supply center;

* Intelligent maintenance system, optional: remote monitoring and maintenance module;

* The compound pulsation process eliminates the indoor air more thoroughly, improves the fatigue life of the equipment, and has a better drying effect.

|

Chamber Design Pressure

|

-0.1~0.3MPa

|

Chamber Safety Valve Openning Pressure

|

0.28MPa

|

|

Jacket Design Pressure

|

0.3MPa

|

Jacket Safety Valve Openning Pressure

|

0.28MPa

|

|

Design Temperature

|

150℃

|

Temperature Control Precision of Sterilization Temperature

|

0~2℃

|

|

Max. Working Temperature

|

139℃

|

Temperature Uniformity

|

±1℃

|

|

Max. Working Pressure

|

0.25MPa

|

Vacuum Amplitude & Frequency of Negative Pressure Pulsation

|

Amplitude -80~0KPa, Frequency 1~99

|

|

Vacuum Leakage Rate

|

≤0.13KPa/min

|

Cross-pressure Pulsation

|

Amplitude -80~80KPa, Frequency 1

|

|

Ultimate Vacuum

|

-97KPa

|

Positive Pressure Pulsation

|

1~3

|

|

Model

|

Chamber Size (W*H*D)mm

|

Volume

|

Overall Size(L*W*H)mm

|

Net Weight

|

Steam Consumption(KG/C)

|

Water Consumption(KG/C)

|

Power Supply

|

Power

|

|

HY-0.25JS

|

550*550*850

|

250L

|

1250*1280*1850

|

750KG

|

18

|

120

|

AC380C, 50HZ

|

2KW+24KW

|

|

HY-0.36JS

|

610*610*1000

|

360L

|

1300*1350*1850

|

850KG

|

22

|

180

|

2KW+30KW

|

|

HY-0.6JS

|

610*910*1200

|

600L

|

1500*1440*1960

|

1250KG

|

35

|

320

|

3KW+36KW

|

|

HY-0.8JS

|

610*910*1500

|

800L

|

1800*1440*1960

|

1350KG

|

47

|

400

|

3.5KW+48KW

|

|

HY-1.2JS

|

680*1180*1500

|

1200L

|

1800*1480*2000

|

1650KG

|

65

|

600

|

3.5KW

|

|

HY-1.5JS

|

680*1180*1850

|

1500L

|

2140*1480*2000

|

1850KG

|

80

|

750

|

4KW

|

|

HY-2.0JS

|

900*1390*1620

|

2000L

|

1970*1750*2200

|

2300KG

|

106

|

1000

|

4.5KW

|

|

HY-2.5JS

|

900*1390*2050

|

2500L

|

2350*1750*2200

|

2700KG

|

132

|

1250

|

6KW

|

|

HY-3.0JS

|

900*1390*2400

|

3000L

|

2700*1750*2200

|

3500KG

|

132

|

1250

|

8KW

|

Optional Customized Volume: 150L/1000L etc.

|

|

24KW, 30KW, 36KW, 48KW are the related power of built-in steam generator.

|

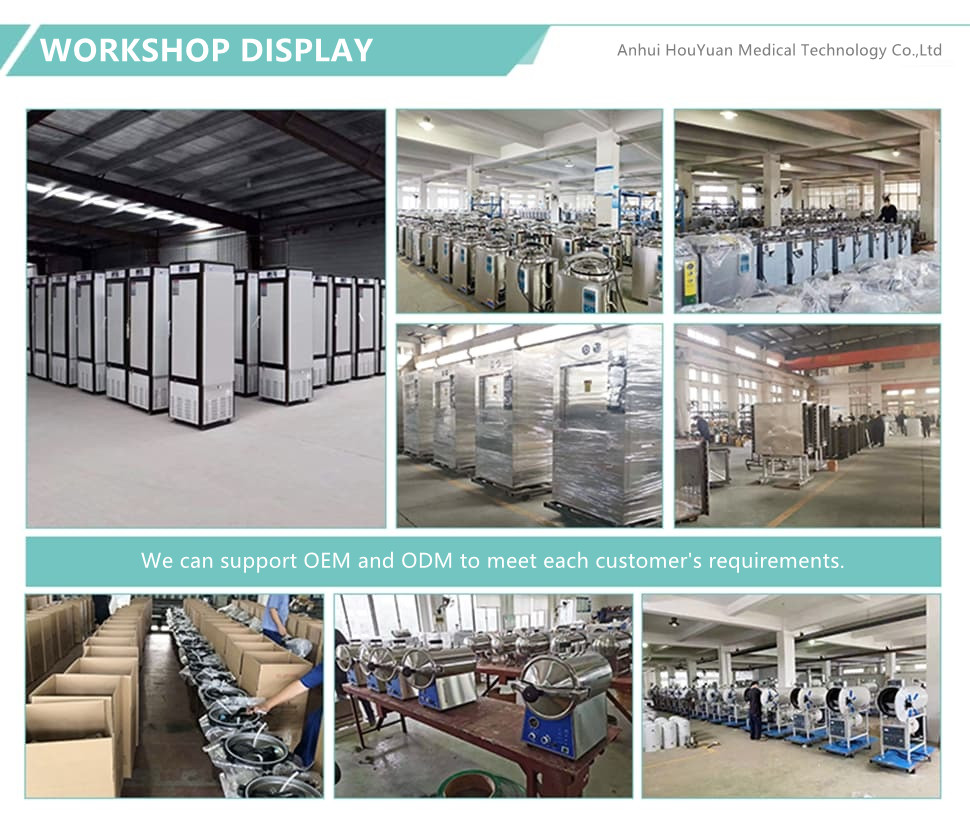

Located in Anhui Province, China--BENOVOR is a professional manufacturer of CSSD Autoclave, Hospital Sterilizers and other relevant medical autoclave sterilizer.

In the past 15 years, BENOVOR has accumulated a large number of technologies and patents, gathered many professional experts, and has become one of the largest manufacturer in medical industrial.

BENOVOR has different types of products with different volumes. With more than 15 years' manufacturing experience, we have exported our products to all of the world.

Customer's satisfaction is our goal.

All the products from BENOVOR has been strictly certificated with CE, ISO 13485 and ISO 9001. Besides, we can support OEM and ODM to meet each customer's requirements.

Committed to the development and production of medical equipment, we strive to do better.

Q: How Can I Choose The Suitable One?

A: Please Tell Us Your Detailed Requirements By Mail or Online, We Will Recommend The Suitable One As Per Your Requests.

Q: Is Your Price Competitive?

A: We Make Sure To Offer You The Best Quality With Competitive Price.

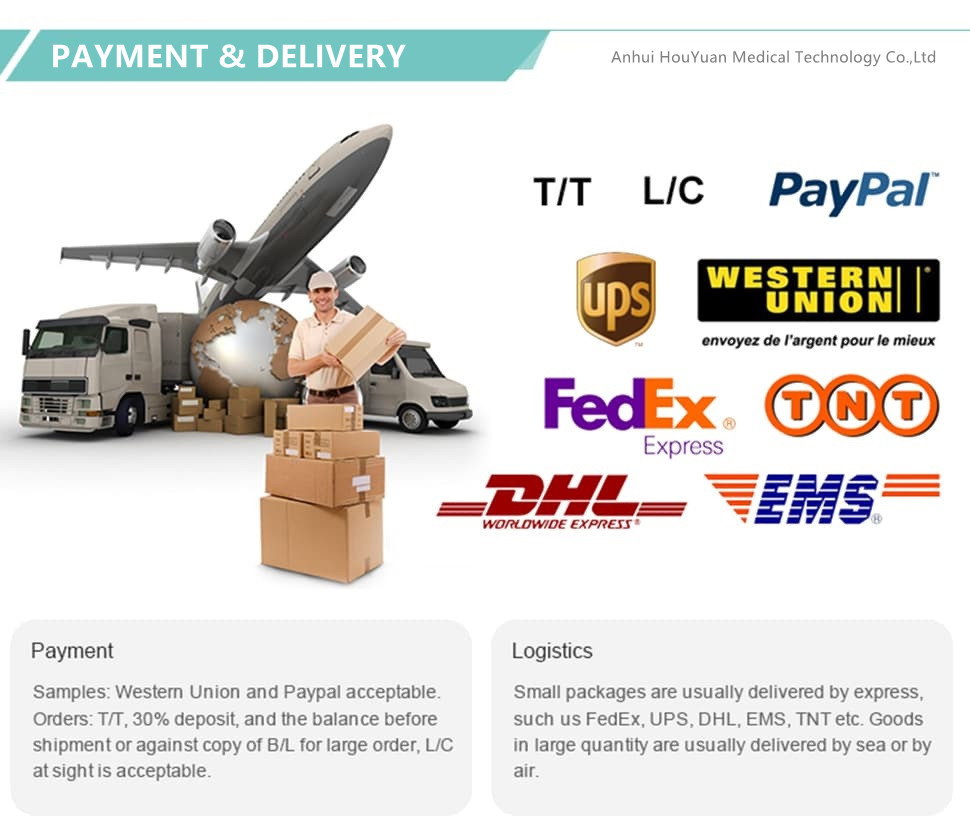

Q: How Can I Pay?

A: We Accept Many Payment Methods, Such As T/T, Western Union, L/C.

Q: When Can I Receive It After Paying?

A: Normal Models Can Be Delivered Within 10-20 Days. Please Contact Us to Check Transport Time to Your Address.

Q: How To Deliver?

A: We Can Send By Express, By Sea And By Air.

Q: Will It Be Broken During Transport?

A: Please Do Not Worry, We Do Standard Export Package.

Q: What Should I Do If I Do Not Know How To Use?

A: Please Do Not Worry, User Manual Will Be Sent Together With Machine And You Can Also Contact Us With More Technical Support.

Q: What Should I Do If Some Parts Are Broken?

A: Please Do Not Worry,We Have 12 Months Warranty For Main Machine And Wearing Parts, We Can Provide Them For Free Within Warranty.

A: All Our Products Have Lifelong After-sale Service With Free Technical Support.

Request for Quotation

Request for Quotation