The most typical varieties of fluoroplastics, PTFE and PVDF have the best corrosion resistance

The most typical varieties of fluoroplastics, PTFE and PVDF have the best corrosion resistance

|

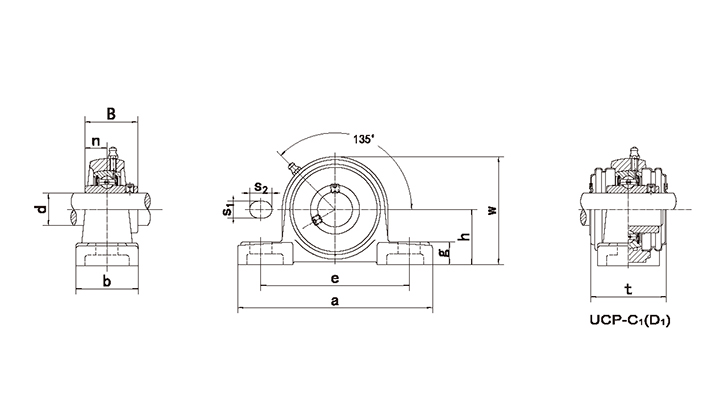

Unit NO. |

Dimensions(mm/in.) |

Max.Torque |

Bearing NO. |

Housing NO. |

Weight (kg) |

|||||||||||

|

d |

h |

a |

e |

b |

s1 |

s2 |

g |

w |

B |

n |

Bolt D |

Nm |

||||

|

SSUCPPL206 |

1-1/16 ; 1-1/8 ; 1-3/16 ; 1-1/4 |

1-11/16 |

6-27/64 |

4-11/16 |

1-13/16 |

9/16 |

45/64 |

45/64 |

3-5/16 |

1.5 |

0.626 |

3/8 |

30 |

SS-UC206 |

PPL206 |

0.54 |

|

SSUCPPL206 |

30 |

42.9 |

163 |

119 |

46 |

14 |

18 |

17.8 |

84 |

38.1 |

15.9 |

M10 |

30 |

SS-UC206 |

PPL206 |

0.54 |

FQN As the SS-UCPPL206 plastic pillow block bearing manufacturer, The plastic bearing unit SS-UCPPL206 is unique in light weight, corrosion resistance, easy installation and maintenance-free. At the same time, it has the shock absorption and shock resistance performance of common cast iron bearing seats or stamped bearing pillow block.

Mainly produced bearing housing models: KFL000-KP007 series, UFL000-UP006 series, P200-P300-PX00 series, F200, F300,FX00 series, FL200,FL300,FLX00 series, T200, FC200,FC300 series, PH200 series, PA200 series, HA200 series, FB200 series, FA200 series, C200 series, PP200 series. Production bearing model: UC, UCX, UK, HC, SA, SB, BC, SER and other specifications with insert bearings

1.Color

Green, black, white

2. Shape

(1) Square block: SF200 series

(2) pillow block: SSUCP200 series

(3) 2-Bolt Flange Bearing Units: SSUCFL200 series

(4) Take-up bearing housing SSUCT200 series

China hot sale SS-UCPPL206 plastic pillow block bearing suppliers

1.Excellent chemical resistance, able to withstand all strong acids (including aqua regia) except molten alkali metals, fluorinated media and sodium hydroxide above 300C, as well as strong oxidants, reducing agents and various organic The role of solvents

2. Excellent heat resistance, its melting temperature is 324°C, decomposition temperature is 415°C, maximum use temperature is 250°C, embrittlement temperature is -190°C, and thermal deformation temperature (under 0.46MPa) is 120°C.

3. It has the smallest surface tension in solid materials and does not adhere to any substances.

4. Low friction performance, friction coefficient is the lowest among known solid materials

5. Resistance to aging

6. Good flexibility

Request for Quotation

Request for Quotation