Certificate :

TUV, CE, IEC,Warranty :

25 years linear warranty

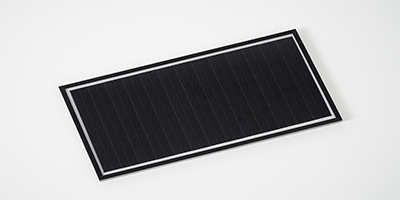

Monocrystalline 10w Black Frame Shingled Solar Panel

Product Details

|

|

| Beautiful appearance | Innovative structure technology |

|

|

| IP68 Junction box | Black frame |

1.More than 7% more electricity: Benefiting from the metal-free grid line design, the shingled module can reduce the line loss by 3% and increase the

light-receiving area by 4% (including reducing the grid line reflection and the gap between the cells),therefore, the power generation can be increased by at least 7%.

2.Extended service life: Breaking through the traditional connection method, the front and rear laminations are used for surface connection, which greatly

improves the reliability of the connection, eliminates the hidden danger of metal grid line breakage, and reduces the risk of metal grid line corrosion and cell cracking.

Product Specification

| MECHANICAL CHARACTERISTICS | ||||||

| Solar Cells | Monocrystalline silicon | |||||

| NO. of Cells | 12(12*1) | |||||

| Dimensions | 350*420*25mm | |||||

| Weight | 0.35kg | |||||

| Junction Box | IP67 rated | |||||

| Front Glass | AR coating tempered glass, 3.2mm | |||||

| Frame | Anodized aluminum profile | |||||

| Output Cables | 4.0mm²,900mm(Be customized by customers) | |||||

| Connectors | MC4 or Customized | |||||

| ELECTRICAL PARAMETERS | ||||||

| Rated Maximum Power (Pmax) [Wp] | 20 | |||||

| Open Circuit Voltage (Voc) [V] | 22.89 | |||||

| Short Circuit Current (Isc) [A] | 1.15 | |||||

| Maximum Power Voltage (Vmp) [V] | 18.46V | |||||

| Maximum Power Current (Imp) [A] | 1.08A | |||||

| Module Efficiency [%] | 22% | |||||

| Working Temperature [°C] | -40°C ~ +85°C | |||||

| Maximum System Voltage | DC 1500 /1000 (IEC) | |||||

| Maximum Series Fuse Rating | 10 | |||||

| Application Class | Class A | |||||

Difference

|

|

| Different welding methods | When shaded by shadow,shingled modules have the best output power if the shingled modules are installed vertically. |

Factory Production

|

|

|

|

Projects

FAQ

1.Why the conversion efficiency of shingled modules is higher than that of conventional modules?

The traditional module packaging technology uses solder tapes to connect the cells in series. It is impossible to have no gaps between the cells. Generally, there will be a spacing of 2-3mm.

For photovoltaic power generation, these areas are ineffective areas that cannot generate electricity. It is because of the existence of these inactive regions that the efficiency of the module is significantly lower than that of the cell.

Shingled solar panel eliminates the weld strip and eliminates these invalid areas, thus greatly improving efficiency.

2.Can you supply the customer with individual packing?

Sure.We can pack according to your instruction.

3.Do you accept sample order?

Sure sample is available.

4.How do your company deal with the problem on quality?

Our company has been doing this industry for more than 10 years .It has already had a certain reputation.We will carefully analyze it.If it is indeed our quality problem,you can rest assured that it will do things according to the contact agreement and will never let you have any after the worries,our service team will be happy to serve you.

Request for Quotation

Request for Quotation