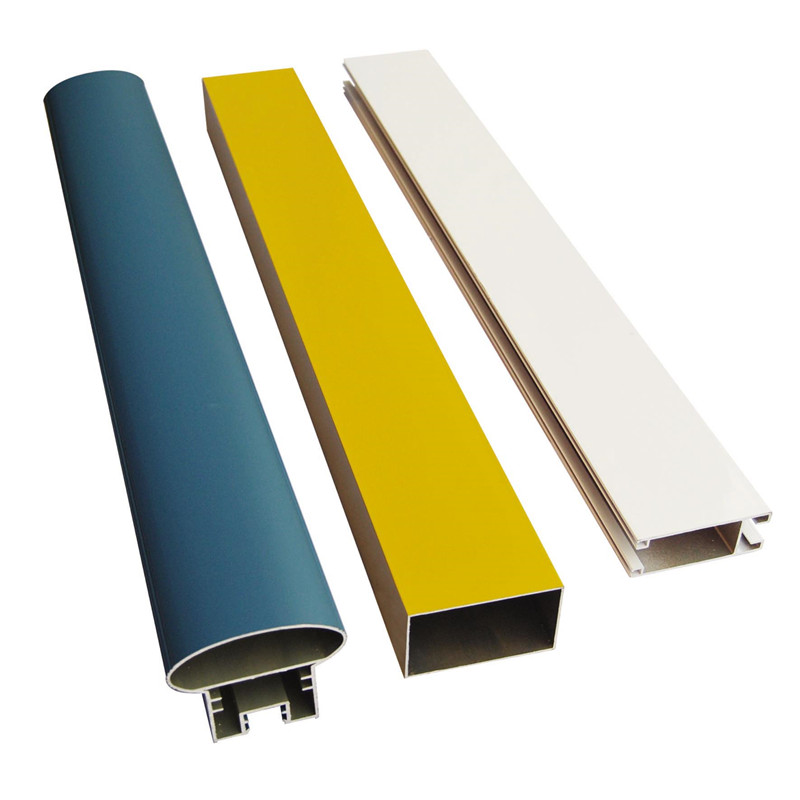

Durable thermal break powder coating aluminium extrusion profile

Quick Details

1. Model :ZCHJ-3009

2.Type: Powder Coating Surface Aluminum Profile

3.Alloy: 6063, 6060, 6061, 6005, 7005

4.Trademark: OEM

5.Price: Based on SMM Aluminium Ingot price(www.smm.cn) + processing Fee

6.Delivery time: 15-30 days if the mould is ready

7.Normal Anodizing thickness: 8-12 micro

8.MOQ: 1*20’ FCL

9.Surface treatment: Anodizing, Powder coating, electrophoresis, wooden finish

10.Length: 1m-7m

Feature

The Powder Coating application is carried out in dust proof facilities that are maintained at a controlled temperature and humidity. The coated profiles are passed through a curing oven for curing of the powder paint on the surface. The polymers used for Powder Coating are polyester, polyester-epoxy (known as hybrid), straight epoxy and acrylics as per customers’ requirements.

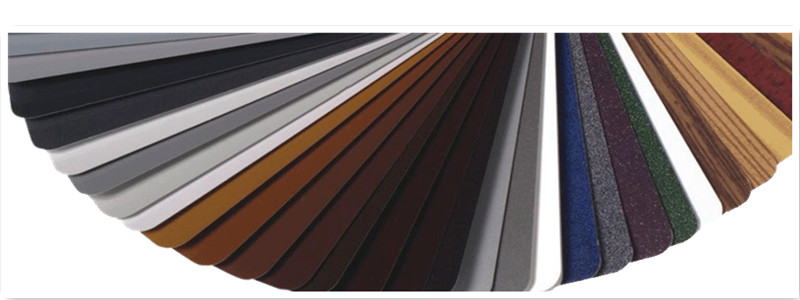

Powder Coated Color

Advantage

For manufacturers and fabricators offering high-quality, reliable and high performance building products, our advantages come standard.

New Construction, Replacements or both.

Residential,Commercial Housing.

Thermal performance requirements.

Structural performance requirements.

Impact requirements.

Compatibility with existing products.

Cost criteria.

Varied width frame depth to accommodate varying types of applications.

Process flow of powder coated aluminium profiles:

Aluminium Billets---Heating Up---Moulding with Raw Aluminium--- Chromation ---aluminium powder coating

Advantaged of our powder coated aluminium profiles:

There are no particles can stay in the air during the processing, which would allow our profile surface color to be smooth enough and without any particles on the surface. Actually this is a technical problem which can hardly be resolved by other factories. corrosion resistan aluminium extrusions is also our product advantage as comparing with other profiles with the same color in the market.

Related Products

Request for Quotation

Request for Quotation