Overview:

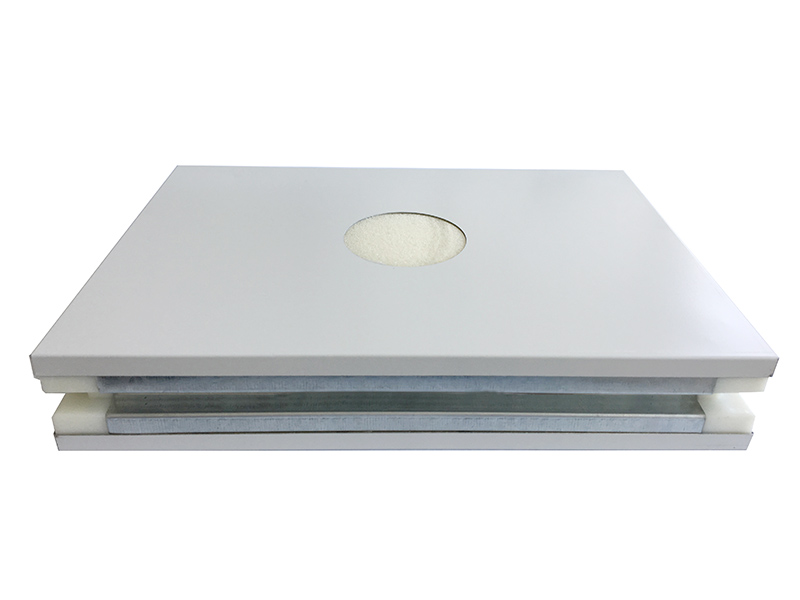

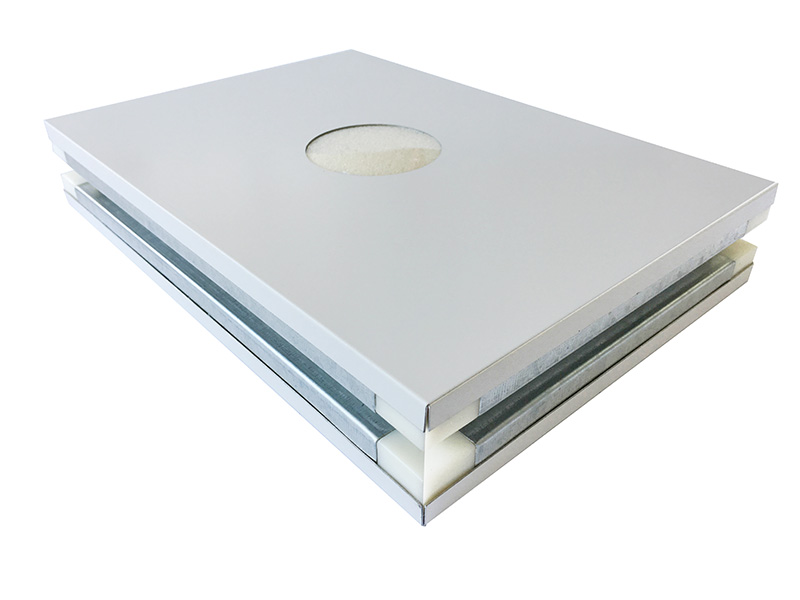

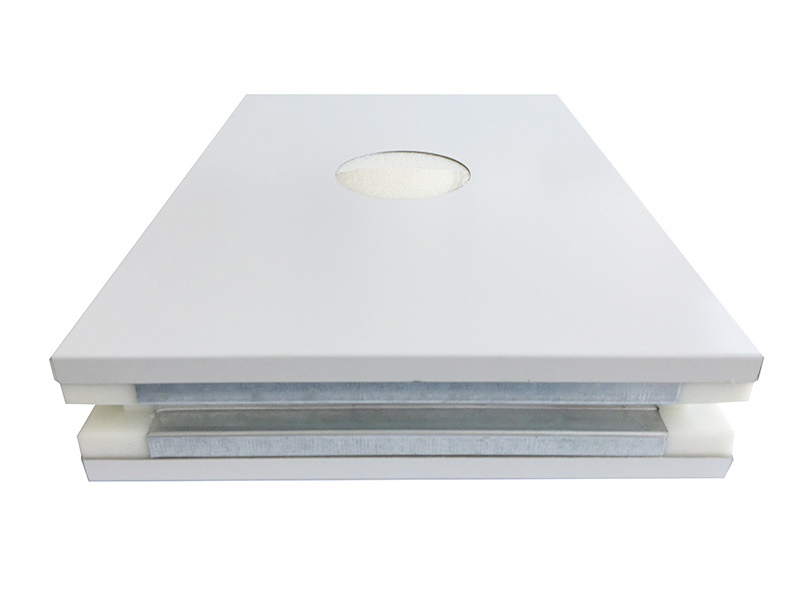

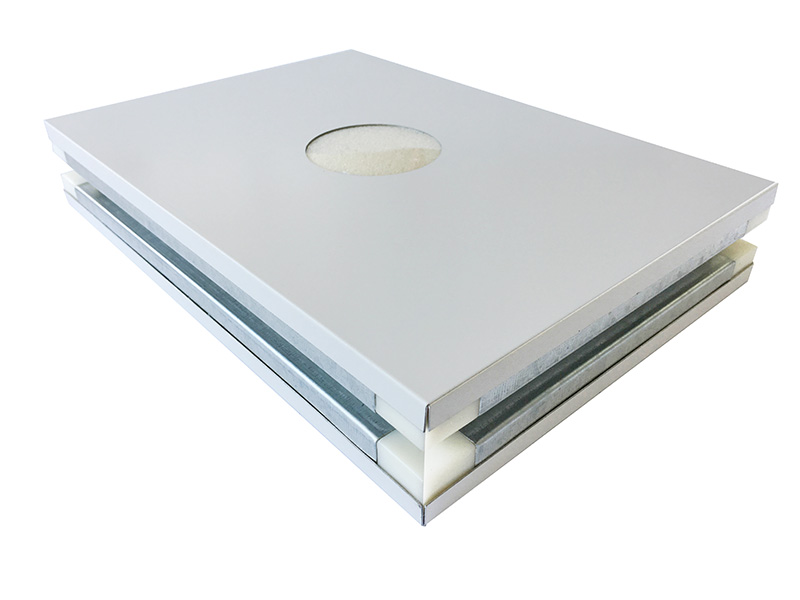

Clean room sandwich panel are main products in clean room engineering, which is not only flame retardant, soundproof and environmentally friendly. The Clean room panel is made up of two layers of m...

Overview:

Clean room sandwich panel are main products in clean room engineering, which is not only flame retardant, soundproof and environmentally friendly. The Clean room panel is made up of two layers of m...

Introduction detail:

Clean room sandwich panels are main products in clean room engineering, which are flame retardant, soundproof and environmentally friendly. The Clean room panel is made up of two layers of metal panels and a functional material from the middle. It has the characteristics of easy installation, light weight and environmental protection. Moreover, the functional materials used for filling can be chosen according to different environments and production requirements. Currently, the core functional materials we can provide are: PU, PIR, Rock Wool, Aluminum Honeycomb, Paper Honeycomb, Magnesium and etc.

Classification:

Rockwool sandwich panel

Rock Wool sandwich panel are usually used for wall or ceilings that have certain requirements for fire resistance. In addition, it has very good thermal insulation properties. Most customers like the rock wool sandwich panels. Rockwool sandwich panels are commonly used in clean room engineering in electronics and pharmaceutical plants. Rock wool is a kind of inorganic fiber board which is made of basalt as the main raw material and melted at high temperature. Rock wool board is a new type of heat preservation, flame insulation and sound absorption material.

The artificial inorganic fiber processed by high temperature melting of rock wool board has the characteristics of light weight, small thermal conductivity, heat absorption and non-combustibility.

The detail of Rockwool sandwich panel:

|

|

HPL sandwich panel

HPL panel (High-pressure laminate) 4 mm thick is a solid compound consisting of more than 40 layers of paper impregnated with melamine and phenolic resins. The sheet of HPL, measuring 1300x3050 mm, has a transparent finishing layer on both external sides that protects the decorative layer below. The central layer, dark brown, is composed of a series of Kraft papers impregnated with phenolic resins, pressed to 9 MPa at 150 °c. It has thermal insulation, fire resistance, easy to installation, nice smoothness and other advantages.

The detail of HPL sandwich panel:

|

|

PU sandwich panel

PU sandwich panel usually named polyurethane sandwich panel 、PU color steel panel or PU composite panel , it has three layers that is the double color steel sheet and the PU core, also have good insulation feature and smoothness.

Polyurethane material is a polymer material. Polyurethane is an emerging organic polymer material and is known as the “fifth largest plastic”. It is widely used in many fields of the national economy due to its excellent performance. Product applications include light industry, chemical, electronics, textile, medical, construction, building materials, automotive, defense, aerospace, aviation and so on.

The detail of PU sandwich panel:

|

|

PIR sandwich panel

PIR core introduction: Polyisocyanurate foam refers to a foamed plastic containing an isocyanurate ring in its molecular structure. In addition to the excellent thermal insulation properties of polyurethane rigid foam and the advantage of good strength at low density, it is common with ordinary Compared with polyurethane rigid foam, its biggest feature is its good flame retardant performance and temperature resistance. Especially its better flame retardant performance has attracted wide attention. Therefore, it has been obtained at home and abroad in recent years. Rapid development.

The detail of PIR sandwich panel:

|

|

Magnesium sandwich panel

Magnesium core introduction: The glass magnesium board has high temperature resistance, flame retardant, sound absorption, shockproof, insect proof, water-proof and moisture proof, light antiseptic, non-toxic, tasteless and non-polluting, high strength, bending resistance, toughness, nailing, sawing, sticking and convenient decoration. It can also be combined with a variety of insulation materials to form composite insulation panels.

Product use: can be used as wallboard, ceiling board, fireproof board, waterproof board, can be combined with a variety of insulation materials to make composite insulation board.

The detail of Magnesium sandwich panel:

|

|

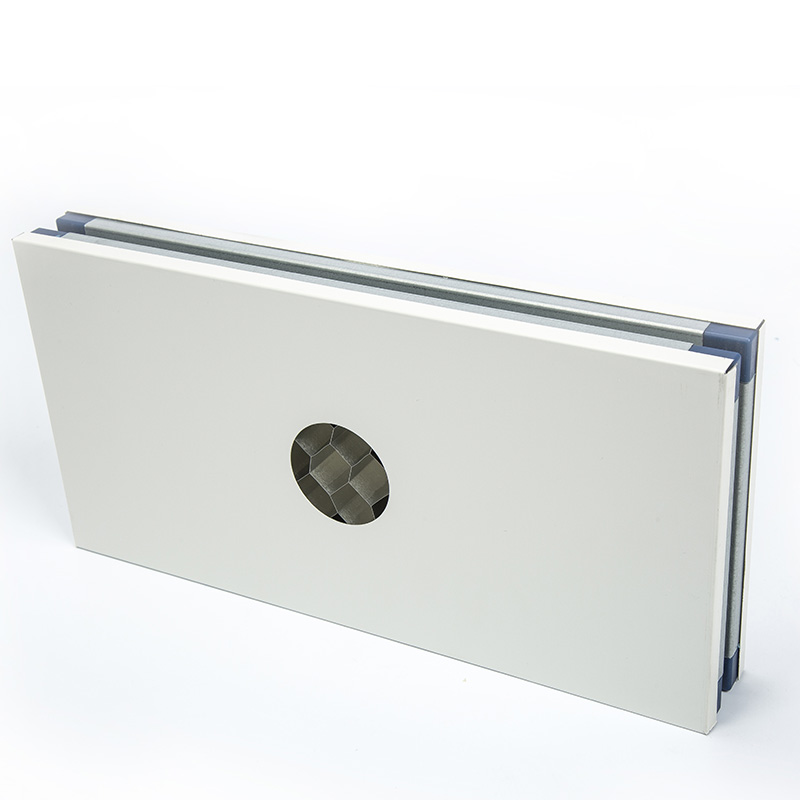

Honeycomb sandwich panel

Honeycomb core introduction: Aluminum hexagonal honeycomb, low density, 1/5 of the same thickness of the same board, 1/6 of the glass, 1/7 of the aluminum, greatly reducing the construction load and cost, because the middle interlayer contains a lot of air, Sound insulation (air insulation up to 30dB), heat insulation (thermal resistance up to 0.02 (m2 · K / W)), no flammable substances, fire rating up to A1, waterproof, moisture-proof, no harmful gas release, aluminum honeycomb panel surface It has extremely high flatness and good seismic performance, only one-eighth of the specific gravity of the glass curtain wall; the 22mm thick standard can achieve a load of 700 kilograms or more at a simple support of 1 meter and a deflection of 10mm. Aluminum honeycomb panels have been widely used in clean room partitions and ceilings due to their advantages of light weight, high strength and high rigidity.

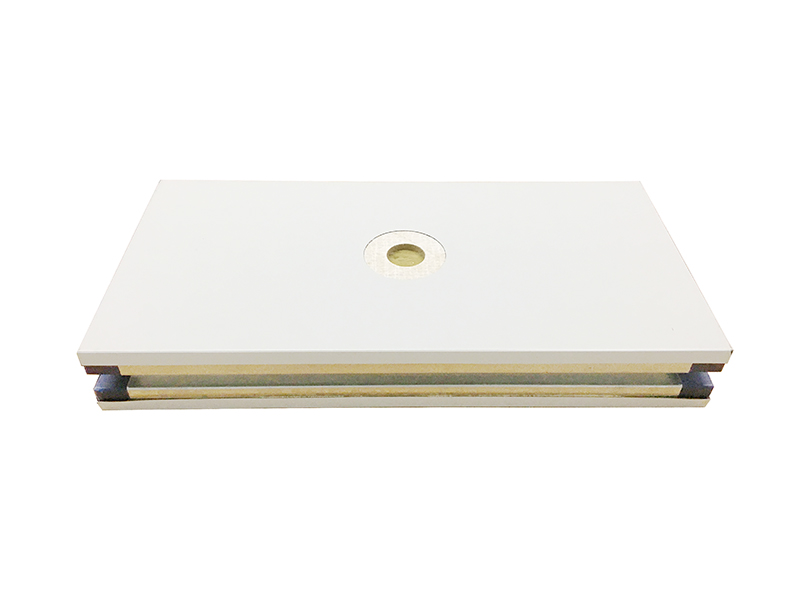

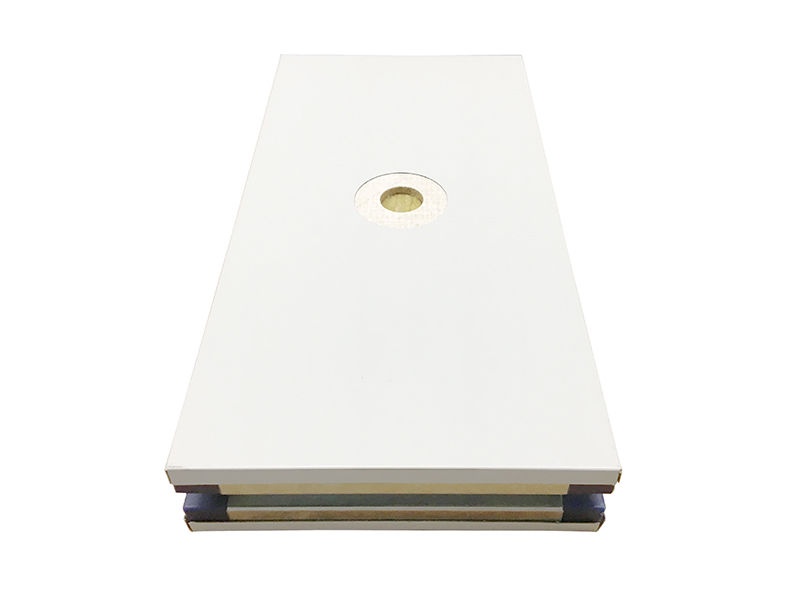

The detail of Honeycomb sandwich panel:

|

|

Request for Quotation

Request for Quotation