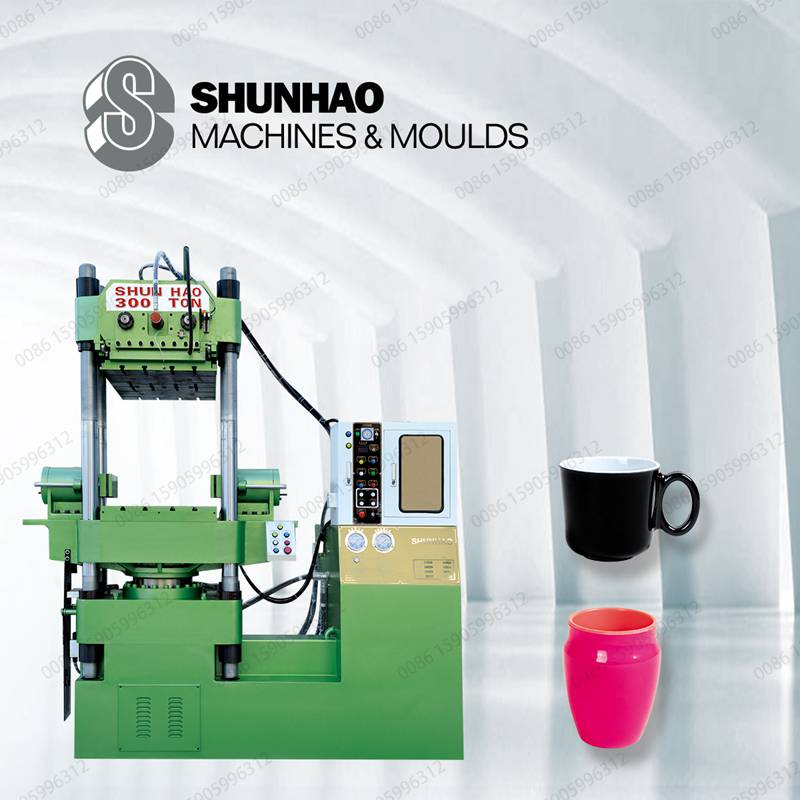

- highly automatic, all functional parameters can be set

- Suitable for producing: double color melamine products

Support Service :

Life-time ServiceTrainning Service :

YesMachine Weight :

7400KGSMachine Dimension :

2.28*1.4*2.87MFeatures of Melamine Tableware Compression Machine:

1. The melamine tableware forming machine has a high degree of computer integration, and all functional parameters can be set through the computer screen;

2. The speed, pressure, deflation times, molding time and various molding modes of the melamine tableware molding machine are recorded and permanently saved, and can be used after being recalled;

3. The melamine tableware making machine adopts heat treatment steel plate with high hardness, high precision after grinding, wear resistance and impact resistance speed;

4. The operation process of the melamine tableware forming machine is simple and easy to learn, no noise and no dust pollution, and the machine can be operated automatically;

5. The machine can be divided into two sections to advance and retreat the mold. The pressing speed can be independently selected on the computer display. If the product does not need to automatically eject the mold, there is a switch that does not eject the mold;

6. The vertical pressure is stable, the extrusion on both sides is carried out simultaneously, and the pressure on the left and right is uniform, which greatly avoids the disadvantages of uneven pressure and residual internal stress;

7. Produce qualified products in the first time, greatly reducing the scrap rate;

8. The melamine tableware molding machine is suitable for all kinds of people to use and operate, instead of non-technical operation

Transportation of melamine tableware compression machine

Safe transportation is our first concen. We will use strudy wood as the basic for the machine, or use the steel cable to fix the lifting hole of the top machine, lock the nut, and then use the cable to lift the pulley to move to the destination and at the same time ensuring its balance .

Installation of tableware molding machine click for more details

1. Use a lever meter to test the balance of the machine to maintain the function of the machine and precision electrical instruments.

2. Use a chillerto keep the oil temperature constant. The device uses 3 / 4-inch pipe threads to connect the inlet / outlet pipes. It is best to use the normal temperature of tap water.

3. Open the junction box on the back of the operation panel, and then connect the three R.S.T connectors to the power cord. The maximum rated pressure of the hydraulic press is 210kg / cm2.

Technical Parameters

|

No. |

Content |

DTS 300 |

DTS 300 Down-press |

|

1 |

Main Cylinder Nominal Pressure |

300Tons. Single color |

300Tons Single color |

|

2 |

Cup Mould Cylinder Nominal Pressure |

106Tons |

200Tons |

|

3 |

Maximum Working Pressure |

210kg/ cm2 |

210kg/ cm2 |

|

4 |

Main Cylinder Piston Diameter |

Ø450mm |

Ø450mm |

|

5 |

Main Cylinder Working Stroke |

560mm |

600mm |

|

6 |

Adjustable Table Distance |

500~960mm |

500~960mm |

|

7 |

Heating Plate Size |

720*720mm |

720*720mm |

|

8 |

Working Layers |

1 layer |

1 layer |

|

9 |

Heating Plate Material |

45# |

45# |

|

10 |

Tension Column (Heat Treatment Grinding) |

Ø120*2400mm |

Ø120*2400mm |

|

11 |

Oil Hydraulic Pump |

21Mpa |

21Mpa |

|

12 |

Motor Specifications |

15HP |

15HP |

|

13 |

Heating Sheet Total Power |

18.6KW |

18.6KW |

|

14 |

Machine Total Power |

29.9KW |

29.9KW |

|

15 |

Machine Size(length * width * height) |

2.28*1.4*2.87M |

3.90*1.4*2.90M |

|

16 |

Machine Weight |

7400KGS |

9600KGS |

PS: Specifications subject to change without notice

Melamine Crockery Making Machine Environment Requirement

Melamine Ware Compression Machine is a big and heavy machine,it needs to meet the following conditions to work:

1. Leave appropriate space for the machine.

2. Keep away from damp or overheated places.

3. Keep the workshop well ventilated.

4. Beware of electricity leakage and water stains

5. Take fire prevention measures

Request for Quotation

Request for Quotation