Certification :

CE, EAC, ISO9001, OHSAS18001, TS16949, SGSShipping Port :

ShenzhenPlace of Origin :

ChinaPackage :

Standard Export Package Carton/WoodAvailability :

OEM/ODM, Minmum Order RequestDelivery Time :

5-7 working days for standard series; 7-14 working days for customized AC drivesTransportation :

Express · Sea freight · Land freight · Air freightWarranty :

18 MonthsCustomized :

YESTerm of payment :

T/T, L/C, D/PSample freight payer :

BuyerSample provide :

YES

Product Overview

| Item | Description |

| Product Name | Frequency Inverter/ AC Drive |

| Model Number | V9-H-4TxxG/xxL |

| Power Range | 0.75kW-630kW |

| Rated Input Voltage | 3 phase 380V/480V |

| Rated Output Voltage | 3 phase 0 to rated input voltage |

| Input Frequency | 50Hz/60Hz |

| Adaptable Motor | Asynchronous Motor, Synchronous Motor |

| Control Mode | V/F Control, Vector Control, Sensorless Vector Control, Sensor Vector Control, Vector Torque Control |

| Communication | Modbus 485 RTU, CANOpen, Profibus-DP, Profinet |

| IP Class | Standard IP20 |

| Overload Capacity | 150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature) |

Feature

■ Fast and accurate motor parameter self-learning, suitable for a variety of motors: synchronous/asynchronous/reluctance/high-speed/torque motor, VF vector encoder closed loop integrated

■ Asynchronous and non-inductive VF control, 200% torque output at 0.25Hz in electric state, 200% torque output at 1Hz in power generation state

■ Good voltage and current control, high speed, high frequency, deep field weakening, wave-by-wave current limiting, multiple protections

■ Modular compact structure design, high power density

■ Support multiple encoders and multiple high-speed communication protocols

■ Integrated drive and control, expandable PLC and motion control card

■ Multiple language keyboard, friendly interface, reliable and easy to use

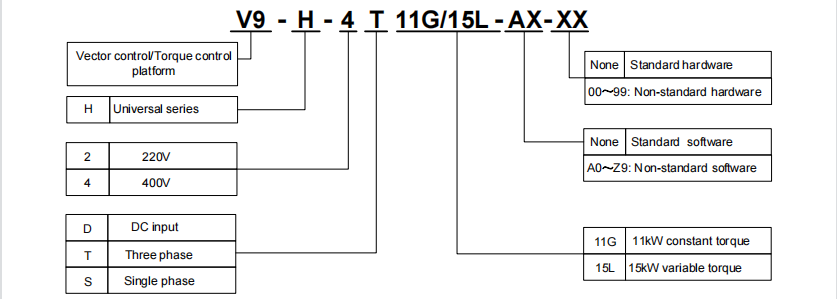

Model Explanation

Product Catalogue

V9−H−4T□□□G Three-phase 400V constant torque / heavy duty Application

| Power(kW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | |

| Motor power (kW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | |

| Output | Voltage (V) | 3-phase 0 -rated input voltage | ||||||||||||||||

| Rated current (A) | 2.5 | 3.8 | 5.5 | 9 | 13 | 17 | 24 | 30 | 39 | 45 | 60 | 75 | 91 | 112 | 150 | 176 | 210 | |

| Overloa capability | 150% 1min,180% 10s, 200% 0.5s,10min interval (Inverse-time characteristic) | |||||||||||||||||

| Input | Rated voltage / frequency | 3-phase 380V-480V;50Hz/60Hz | ||||||||||||||||

| Allowabl voltage | 323V-528V;degree of voltage unbalance:≤3%;allowable frequency fluctuations:±5% | |||||||||||||||||

| Rated current (A) | 2.8 | 4.2 | 6.1 | 10 | 15 | 19 | 26 | 33 | 43 | 50 | 66 | 83 | 100 | 123 | 165 | 194 | 231 | |

| Brake unit | Standard built-in | Built-in brake unit is optional | ||||||||||||||||

| Protection level | IP20 | |||||||||||||||||

| Cooling method | Self−cooling | Forced cooling | ||||||||||||||||

| Power(kW) | 132 | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | 560 | 630 | |

| Motor power (kW) | 132 | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | 560 | 630 | |

| Output | Voltage (V) | 3-phase 0 -rated input voltage | |||||||||||||

| Rated current (A) | 253 | 304 | 350 | 380 | 426 | 470 | 520 | 600 | 650 | 690 | 775 | 860 | 950 | 1100 | |

|

Overload

capability

|

150% 1min,180% 10s, 200% 0.5s,10min interval (Inverse-time characteristic) | ||||||||||||||

| Input | Rated voltage / frequency | 3-phase 380V-480V;50Hz/60Hz | |||||||||||||

| Allowable voltage | 323V-528V;degree of voltage unbalance:≤3%;allowable frequency fluctuations:±5% | ||||||||||||||

| Rated current (A) | 232 | 282 | 326 | 352 | 385 | 437 | 491 | 580 | 624 | 670 | 755 | 840 | 920 | 1050 | |

| Brake unit | External braking unit needed | ||||||||||||||

| Protection level | IP20 | ||||||||||||||

| Cooling method | Forced cooling | ||||||||||||||

Note:* 0.75kW~15kW:no built-in DC reactor ;

18.5kW~110kW:optional DC reactor ;

132kW~160kW:standard built-in DC reactor ;

185kW~500kW:standard external DC reactor

560kW~630kW:standard built-in AC input reactor

Higher power level product can be customized

220V, 690V, 1140V and other voltage level inverters can be ;customized

V9−H−4T□□□L Three−phase 400V Variable torque/light−duty Application

| Power(kW) | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | 132 | |

| Motor power (kW) | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | 132 | |

| Output | Voltage(V) | 3-phase 0 -rated input voltage | ||||||||||||||||

| Rated current (A) | 3.3 | 5 | 7.5 | 11 | 17 | 22 | 29 | 35 | 45 | 57 | 70 | 91 | 110 | 144 | 180 | 216 | 242 | |

| Overload capability | 120% 1min,160% 0.5s,10min interval (Inverse-time characteristic) | |||||||||||||||||

| Input | Rated voltage /frequency | 3-phase 380V-480V;50Hz/60Hz | ||||||||||||||||

|

Allowable

voltage

|

323V-528V;degree of voltage unbalance:≤3%;allowable frequency fluctuations:±5% | |||||||||||||||||

| Rated current (A) | 3.6 | 5.5 | 8.3 | 12 | 19 | 25 | 32 | 39 | 50 | 61 | 77 | 100 | 121 | 158 | 198 | 238 | 266 | |

| Brake unit | Standard built-in | Built-in brake unit is optional | ||||||||||||||||

| Protection level | IP20 | |||||||||||||||||

| Cooling method | Self−cooling | Forced cooling | ||||||||||||||||

| Power(kW) | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | 560 | 630 | 710 | |

| Motor power (kW) | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | 560 | 630 | 710 | |

| Output | Voltage (V) | 3-phase 0 -rated input voltage | |||||||||||||

|

Rated current

(A)

|

325 | 365 | 405 | 440 | 495 | 547 | 610 | 695 | 770 | 866 | 950 | 1100 | 1200 | 1300 | |

| Overload capability | 120% 1min,160% 0.5s,10min interval (Inverse-time characteristic) | ||||||||||||||

| Input | Rated voltage /frequency | 3-phase 380V-480V;50Hz/60Hz | |||||||||||||

|

Allowabl

voltage

|

323V-528V;degree of voltage unbalance:≤3%;allowable frequency fluctuations:±5% | ||||||||||||||

| Rated current (A) | 282 | 326 | 352 | 385 | 437 | 491 | 580 | 670 | 755 | 840 | 920 | 1050 | 1150 | 1250 | |

| Brake unit | External braking unit needed | ||||||||||||||

| Protection level | IP20 | ||||||||||||||

| Cooling method | Forced cooling | ||||||||||||||

200kW~560kW: standard external DC reactor ;

22kW~132kW: optional DC reactor ;

160kW~185kW: standard built-in DC reactor ;

630kW~710kW: standard built-in AC input reactor

Higher power level product can be customized ;

220V, 690V, 1140V and other voltage level inverters can be customized

Technical Specification

|

Control characteristics |

Control ;mode |

Sensor-less control |

Sensor control |

|

Applicable motor type |

Synchronous motor Asynchronous motor |

Synchronous motor Asynchronous motor |

|

|

Starting torque |

● Asynchronous motor: 200% of rated torque at 0.25Hz ● Synchronous motor: 150% of rated torque at 1.5% of rated speed

|

200% of rated torque at 0 speed |

|

|

Speed regulation range |

1:200 |

1:5000 |

|

|

Steady speed precision |

± 0.5% |

± 0.02% |

|

|

Maximum speed |

VF control: 600Hz Vector control: 600 Hz ; Note: Higher frequency products can be customized |

600Hz Note: Higher frequency products can be customized |

|

|

Torque control |

Y |

Y |

|

|

Torque control precision |

±5% |

±3% |

|

|

Torque response time |

<20ms |

<10ms |

|

|

Positioning control |

N |

Y |

|

|

Positioning precision |

N |

±1 ;pulse |

|

|

Product function |

Key function |

Torque limit, speed control, positioning control, motor ;auto tune, ;deep ;flux-weakening ;control, current limit control, over-voltage control, under-voltage control, ;motor ;speed tracing function, droop control, oscillation suppression, random carrier frequency, inertia auto-tune, etc. |

|

|

Speed reference source |

Modbus communication, Keypad, ;external digital input, analog ;AI1/AI2/AI3, ;high speed pulse input, ;simple PLC, PID, ;CAN, PROFIBUS DP, PROFINET, ;etc. |

||

|

Dynamic brake |

Brake unit action voltage: 650 ~ 750V. The brake unit can be built-in for ;110kW ;and below equipment ● 0.75~15kW: brake unit is built- in as standard. ● 18.5~110kW: brake unit is built- in as optional. |

||

|

Communication |

Built-in Modbus-RTU communication, the maximum distance up to 500 meters. |

||

|

Keypad |

LED Keypad and LCD Keypad are optional the Keypad can be used as ;remote-control box ;via straight-through wired cable. ; |

||

|

Common DC bus |

Support common DC bus ;directly |

||

|

Independent air duct |

All series product adopts independent duct design |

||

|

Protection function |

Power supply under-voltage, over-current protection, over-voltage protection, ;auto-tune fault, module protection, heat-sink overtemperature ;protection, drive overload protection, motor overload protection, peripheral protection, current ;abnormal ;detection, output short-circuit ;to ;ground protection, EEPROM abnormal detection, temperature sampling disconnection, encoder disconnection, analog input abnormal detection, motor overtemperature, communication ;fault, hardware overload protection, etc. |

||

|

Efficiency |

At rating condition: ● 0.75kW to ;7.5kW: ;≥93% ● 11kW to ;45kW: ;≥95% ● 55kW and ;higher ;power class: ;≥98% |

||

|

Environment |

Operating site |

● Install vertically in a well-ventilated electrical cabinet. Horizontal or other installation methods are not allowed. ● The cooling medium is air. ● Installed in an environment free from direct sunlight, dust, corrosive gases, flammable gases, no oil mist, no steam, no dripping. |

|

|

Ambient temperature |

● −10~+40℃ ● Derating use when the temperature between 40 to 50℃, the rated output current is reduced by 1% for every 1 °C increasing. |

||

|

Humidity |

5~95%, ;no condensation is allowed. |

||

|

Altitude |

● 0~2000 ;meters ● Derating use when the altitude over 1000 meters, the rated output current is reduced by 1% for every 100-meter rising. |

||

|

Vibration |

● 3.5 m/s2, ;2~9Hz ● 10 m/s2, ;9~200Hz ● 15 m/s2, ;200~500Hz |

||

|

Storage temperature |

−40~+70℃. |

||

Installation dimension

|

|

V9−H−4T7.5G/11L and below power class

|

|

V9−H−4T11G/15L and above power class

|

Voltage |

Model |

Outline and mounting dimension (mm) |

Weight (kg) |

||||||

|

W |

H |

D |

W1 |

H1 |

T1 |

Mounting hole diameter ;d |

|||

|

400V |

V9−H−4T0.75G/1.5L |

118 |

190 |

155 |

105 |

173 |

3 |

5.5 |

1.5 |

|

V9−H−4T1.5G/2.2L |

118 |

190 |

175 |

105 |

173 |

4 |

5.5 |

2.6 |

|

|

V9−H−4T2.2G/3.7L |

|||||||||

|

V9−H−4T3.7G/5.5L |

|||||||||

|

V9−H−4T5.5G/7.5L |

155 |

249 |

185 |

136 |

232 |

8 |

5.5 |

3 |

|

|

V9−H−4T7.5G/11L |

|||||||||

|

V9−H−4T11G/15L |

198 |

299 |

190 |

160 |

283 |

1.2 |

6 |

8 |

|

|

V9−H−4T15G/18.5L |

|||||||||

|

V9−H−4T18.5G/22L |

223 |

348 |

208 |

195 |

335 |

1.5 |

6 |

10 |

|

|

V9−H−4T22G/30L |

|||||||||

|

V9−H−4T30G/37L |

264 |

430 |

235 |

230 |

418 |

1.5 |

7 |

18 |

|

|

V9−H−4T37G/45L |

|||||||||

|

V9−H−4T45G/55L |

305 |

545 |

270 |

245 |

523 |

1.5 |

10 |

35 |

|

|

V9−H−4T55G/75L |

|||||||||

|

V9−H−4T75G/90L |

338 |

580 |

310 |

270 |

560 |

1.5 |

10 |

52 |

|

|

V9−H−4T90G/110L |

|||||||||

|

V9−H−4T110G/132L |

|||||||||

|

V9−H−4T132G/160L |

400 |

917 |

323 |

320 |

890 |

3.0 |

12 |

75 |

|

|

V9−H−4T160G/185L |

|||||||||

|

V9−H−4T185G/200L |

540 |

890 |

385 |

370 |

855 |

4.0 |

14 |

85 |

|

|

V9−H−4T200G/220L |

|||||||||

|

V9−H−4T220G/250L |

540 |

890 |

416 |

370 |

855 |

4.0 |

14 |

85 |

|

|

V9−H−4T250G/280L |

700 |

1010 |

385 |

520 |

977 |

4.0 |

14 |

125 |

|

|

V9−H−4T280G/315L |

|||||||||

|

V9−H−4T315G/355L |

700 |

1010 |

418.5 |

520 |

977 |

4.0 |

14 |

125 |

|

|

V9−H−4T355G/400L |

810 |

1358 |

425 |

520 |

1300 |

4.0 |

14 |

215 |

|

|

V9−H−4T400G/450L |

810 |

1358 |

425 |

520 |

1300 |

4.0 |

14 |

215 |

|

|

V9−H−4T450G/500L |

|||||||||

|

V9−H−4T500G/560L |

|||||||||

Applications

|

|

|

|

|

|

|

|

|

Representative Industry

Printing Packaging, Petrochemical, Textile, Cable Machinery, Food Packaging, Electric Vehicles, Plastic Machinery, Metal ;Products Equipment, Centrifuges and High-end applications requiring closed-loop vector or torque control.

Request for Quotation

Request for Quotation