Certification :

CE, EAC, ISO9001, OHSAS18001, TS16949, SGSShipping Port :

ShenzhenPlace of Origin :

ChinaAvailability :

OEM/ODM, Minmum Order RequestPackage :

Standard Export Package Carton/WoodTransportation :

Express · Sea freight · Land freight · Air freightWarranty :

18 MonthsDelivery Time :

5-7 working days for standard series; 7-14 working days for customized AC drivesTerm of payment :

T/T, L/C, D/PCustomized :

YESSample freight payer :

BuyerSample provide :

YES

Product Overview

| Item | Description |

| Product Name | Frequency Inverter/ AC Drive |

| Model Number | V6-H-4TxxG/xxL |

| Power Range | 0.75kW-500kW |

| Rated Input Voltage | 3 phase 380V/480V |

| Rated Output Voltage | 3 phase 0 to rated input voltage |

| Input Frequency | 50Hz/60Hz |

| Adaptable Motor | Asynchronous Motor |

| Control Mode | V/F Control, Vector Control, Sensorless Vector Control, Sensor Vector Control, Vector Torque Control |

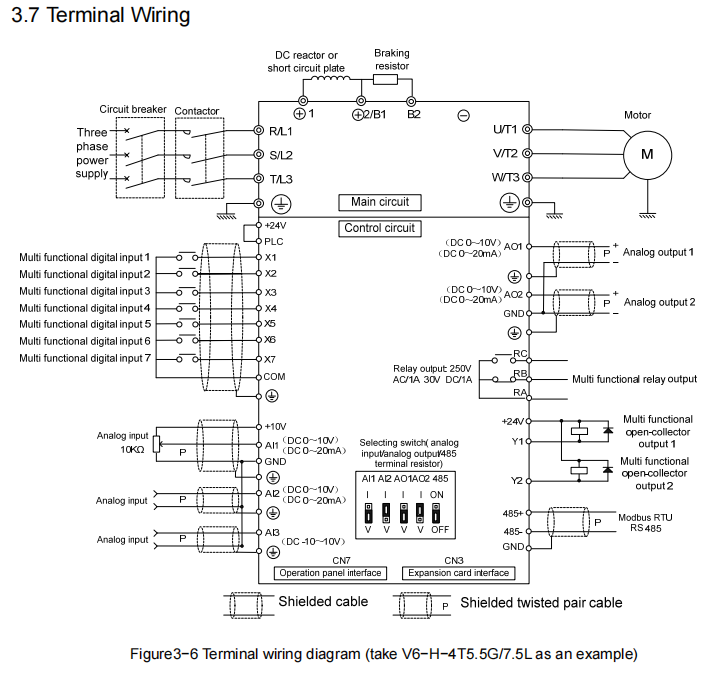

| Communication | Modbus 485 RTU |

| IP Class | Standard IP20 |

| Overload Capacity | 150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature) |

Feature

■ Open - loop vector, Closed - loop vector, Open - loop torque, Closed - loop torque control.

■ Inverter operates stably without tripping under any acceleration and deceleration time and any impact load.

■ Real torque control is realized through the independent current loop control, and online switching between torque control and speed control is supported.

■ Independent input and output port of high speed pulse, which can realize high speed pulse cascade function.

■ Accurate speed identification and rotor flux orientation, the torque can also respond quickly and operate stably when a load of 0.25hz breaks.

■ High-precision current detection and protection, high-precision hall to detect output current, realization of fast real-time control and protection of software and hardware, and assurance of performance and reliability of the whole machine.

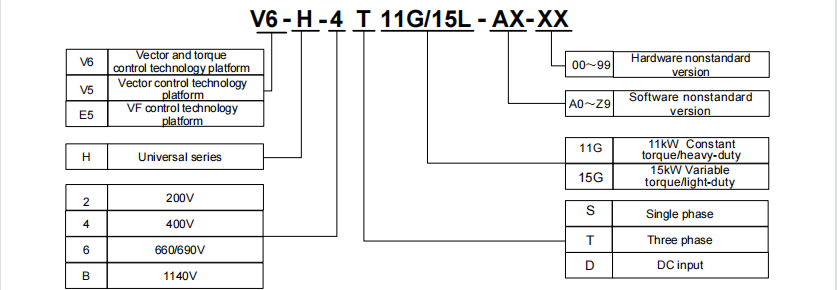

Model Explanation

Product Catalogue

V6−H−4T□□□G Three−phase 400V Constant torque/heavy−duty application

| Power (kW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | |

| Motor power (kW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | |

| Output | Voltage (V) | Three-phase 0 to rated input voltage | ||||||||||||||

| Rated current (A) | 2.5 | 3.8 | 5.5 | 9 | 13 | 17 | 24 | 30 | 39 | 45 | 60 | 75 | 91 | 112 | 150 | |

| Overload capacity | 150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag ;feature) | |||||||||||||||

| Input | Rated voltage/frequency | Three-phase 380V/480V; 50Hz/60Hz | ||||||||||||||

| Allowable voltage range | 323V ~ 528V; Voltage imbalance ;≤3%; allowable frequency fluctuation: ±5% | |||||||||||||||

| Rated current (A) | 2.8 | 4.2 | 6.1 | 10 | 15 | 19 | 26 | 33 | 43 | 50 | 66 | 83 | 100 | 123 | 165 | |

| Braking unit | Built-in as standard | Built-in as option | ||||||||||||||

| Protection class | IP20 | |||||||||||||||

| Cooling mode | Natural−cooling | Forced air cooling | ||||||||||||||

| Power (kW) | 90 | 110 | 132 | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | ||

| Motor power (kW) | 90 | 110 | 132 | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | ||

| Output | Voltage (V) | Three-phase 0 to rated input voltage | ||||||||||||||

| Rated current (A) | 176 | 210 | 253 | 304 | 350 | 380 | 426 | 470 | 520 | 600 | 650 | 690 | 775 | 860 | ||

| Overload capacity | 150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag ;feature) | |||||||||||||||

| Input | Rated voltage/frequency | Three-phase 380V/480V; 50Hz/60Hz | ||||||||||||||

| Allowable voltage range | 323V ~ 528V; Voltage imbalance ;≤3%; allowable frequency fluctuation: ±5% | |||||||||||||||

| Rated current (A) | 160* | 196* | 232* | 282* | 326* | 352* | 385* | 437* | 491* | 580* | 624* | 670* | 755* | 840* | ||

| Braking unit | External braking unit needed | |||||||||||||||

| Protection class | IP20 | |||||||||||||||

| Cooling mode | Forced air cooling | |||||||||||||||

V6−H−4T□□□L ;Three−phase 400V Variable torque/light−duty application

| Power (kW) | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | |

| Motor power (kW) | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | |

| Output | Voltage (V) | Three-phase 0 to rated input voltage | ||||||||||||||

| Rated current (A) | 3.3 | 5 | 7.5 | 11 | 17 | 22 | 30 | 37 | 44 | 56 | 72 | 91 | 110 | 142 | 176 | |

| Overload capacity | 115% 1 minute, 160% 0.5 second, interval: 10 minutes (inverse time lag feature) | |||||||||||||||

| Input | Rated voltage/frequency | Three-phase 380V/480V; 50Hz/60Hz | ||||||||||||||

| Allowable voltage fluctuation range | 323V ~ 528V; Voltage imbalance: ≤3%; allowable frequency fluctuation: ±5% | |||||||||||||||

| Rated current (A) | 3.6 | 5.5 | 8.3 | 12 | 19 | 25 | 33 | 40 | 50 | 62 | 80 | 100 | 121 | 156 | 194 | |

| Braking unit | Built-in as standard | Built-in is optional | ||||||||||||||

| Protection class | IP20 | |||||||||||||||

| Cooling mode | Natural cooling | Forced air cooling | ||||||||||||||

| Power (kW) | 110 | 132 | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | 560 | ||

| Motor power (kW) | 110 | 132 | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | 560 | ||

| Output | Voltage (V) | Three-phase 0 to rated input voltage | ||||||||||||||

| Rated current (A) | 210 | 253 | 304 | 350 | 380 | 426 | 470 | 520 | 600 | 650 | 690 | 775 | 860 | 950 | ||

| Overload capacity | 115% 1 minute, 160% 0.5 second, interval: 10 minutes (inverse time lag feature) | |||||||||||||||

| Input | Rated voltage/frequency | Three-phase 380V/480V; 50Hz/60Hz | ||||||||||||||

| Allowable voltage range | 323V ~ 528V; Voltage imbalance ;≤3%; allowable frequency fluctuation: ±5% | |||||||||||||||

| Rated current (A) | 196* | 232* | 282* | 326* | 352* | 385* | 437* | 491* | 580* | 624* | 670* | 755* | 840* | 920* | ||

| Braking unit | External braking unit needed | |||||||||||||||

| Protection class | IP20 | |||||||||||||||

| Cooling mode | Forced air convection cooling | |||||||||||||||

*V6−H−4T110L and higher power products are equipped with external DC reactor as standard.

V6−H−2T□□□G Three−phase 200V Constant torque/heavy−duty application

|

Power (kW) |

0.4 |

0.75 |

1.5 |

2.2 |

||

|

Motor power (kW) |

0.4 |

0.75 |

1.5 |

2.2 |

||

|

Output |

Voltage (V) |

Three−phase 0 to rated input voltage |

||||

|

Rated current (A) |

3 |

5 |

7.5 |

10 |

||

|

Overload capacity |

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes ;(inverse time lag feature) |

|||||

|

Input |

Rated voltage/frequency |

Three−phase or single−phase 200V~240V; 50Hz/60Hz |

||||

|

Allowable voltage range |

180V ~ 260V; Voltage ;imbalance≤3%; allowable frequency fluctuation: ±5% |

|||||

|

Rated current (A) |

3.8 |

5.5 |

8.3 |

12 |

||

|

Braking unit |

Built−in as standard |

|||||

|

Protection class |

IP20 |

|||||

|

Cooling mode |

Natural−cooling |

Forced air cooling |

||||

Technical Specification

|

Control characteristics |

Control mode

|

Vector control 1

|

Vector control 2 (Without encoder) |

Vector control 2 (With encoder ) |

|

Starting torque |

0.50Hz 180% |

0.25Hz 180% |

0.00Hz 180% |

|

|

Range of speed regulation |

1:100 |

1:200 |

1:1000 |

|

|

Precision of steady speed |

± 0.5% |

± 0.2% |

± 0.02% |

|

|

Torque control |

N |

Y |

Y |

|

|

Precision of torque control |

− |

±5% |

±5% |

|

|

Torque response time |

− |

<20ms |

<10ms |

|

|

Product functions |

Key functions |

Under-voltage regulation, switchover of run command source(operation panel, terminal and communication), speed tracing function, torque limit, multi− step frequency reference(up to 23 step frequency), motor data identification, S curve acceleration and deceleration, slip compensation, PID regulation, droop control, current limit, switch-over between torque control and speed control, manual torque boost and auto torque boost, programmable digital inputs and programmable digital outputs |

||

|

Frequency reference mode |

Parameter setting, operation panel UP/DN, terminal, terminal UP/DN, communication, analog ( AI1/AI2/AI3), pulse DI , etc. |

|||

|

Frequency range |

0.00 ~ 300.00Hz Note: In the control mode of vector control 1, frequency range from 0.0Hz to 3000.0Hz can be customized according to the customer demand |

|||

|

Start frequency |

0.00 ~ 60.00Hz |

|||

|

Acceleration time and deceleration time |

0.1 ~ 36000s |

|||

|

Dynamic braking |

Braking unit action voltage: 650 ~ 750V; operating time: 100.0s The braking unit can be built-in for V6−H−4T75G and below equipment |

|||

|

DC braking |

DC braking start frequency: 0.00 ~ 300.00Hz DC braking current: constant torque: 0.0 ~ 120.0%, variable torque: 0.0 ~ 90.0% DC braking time: 0.0 ~ 30.0s; DC braking function does not required waiting time to start to realize quick braking |

|||

|

Magnetic flux braking |

Enabled or disabled during deceleration are optional, the default setting is enabled |

|||

|

Unique functions |

Multi-function M key |

The unique multi-function key can be set to frequently used operations: such as JOG, emergency stop, switchover of run command source, switchover of parameters display mode, etc. |

||

|

Multiple parameters display modes |

Basic parameters display mode, fast parameters display mode, non−factory setting parameters display mode, last changed 10 parameters display mode |

|||

|

Parameters copy |

The standard operation panel can realize the parameters upload, download and display the copy progress. Users can set to forbid overwriting the uploaded parameters |

|||

|

Displayed and hidden parameters group |

The customer can select to display or hide the parameters group by themselves |

|||

|

Dual 485 communication ports |

Dual 485 communication ports support Modbus protocol (RTU). The maximum distance is 500 meters |

|||

Installation dimension

|

|

V6−H−2T0.4G~V6−H−2T2.2G、V6−H−4T7.5G/11L And below power class

|

|

V6−H−4T11G/15L And above power class

Product appearance, installation dimensions, approximate weight

|

Voltage |

Model |

Appearance, installation dimension(mm) |

weight(kg) |

|||||||

|

W |

H |

D |

W1 |

H1 |

D1 |

T1 |

Hole ;d |

|||

|

200V |

V6−H−2T0.4G |

118 |

190 |

155 |

105 |

173 |

40.8 |

3 |

5.5 |

1.5 |

|

V6−H−2T0.75G |

175 |

60.5 |

4 |

2.2 |

||||||

|

V6−H−2T1.5G |

155 |

40.8 |

3 |

1.5 |

||||||

|

V6−H−2T2.2G |

175 |

60.5 |

4 |

2.2 |

||||||

|

400V |

V6−H−4T0.75G/1.5L |

118 |

190 |

155 |

105 |

173 |

40.8 |

3 |

5.5 |

1.5 |

|

V6−H−4T1.5G/2.2L |

118 |

190 |

175 |

105 |

173 |

60.5 |

4 |

5.5 |

2.6 |

|

|

V6−H−4T2.2G/3.7L |

||||||||||

|

V6−H−4T3.7G/5.5L |

||||||||||

|

V6−H−4T5.5G/7.5L |

155 |

249 |

185 |

136 |

232 |

69 |

8 |

5.5 |

4.5 |

|

|

V6−H−4T7.5G/11L |

||||||||||

|

V6−H−4T11G/15L |

210 |

337 |

200 |

150 |

324 |

88 |

2 |

7 |

8.5 |

|

|

V6−H−4T15G/18.5L |

||||||||||

|

V6−H−4T18.5G/22L |

289 |

440 |

215 |

200 |

425 |

88 |

2.5 |

7 |

17 |

|

|

V6−H−4T22G/30L |

||||||||||

|

V6−H−4T30G/37L |

||||||||||

|

V6−H−4T37G/45L |

319 |

575 |

212 |

220 |

553 |

90.5 |

2.5 |

10 |

25 |

|

|

V6−H−4T45G/55L |

||||||||||

|

V6−H−4T55G/75L |

404 |

615 |

255 |

270 |

590 |

86.5 |

3.0 |

10 |

35 |

|

|

V6−H−4T75G/90L |

||||||||||

|

V6−H−4T90G V6−H−4T110L |

465 |

745 |

325 |

343 |

715 |

151.5 |

3.0 |

12 |

55 |

|

|

V6−H−4T110G V6−H−4T132L |

||||||||||

|

V6−H−4T132G V6−H−4T160L |

540 |

890 |

385 |

370 |

855 |

205.5 |

4.0 |

14 |

85 |

|

|

V6−H−4T160G V6−H−4T185L |

||||||||||

|

V6−H−4T185G V6−H−4T200L |

||||||||||

|

V6−H−4T200G V6−H−4T220L |

||||||||||

|

V6−H−4T220G V6−H−4T250L |

700 |

1010 |

385 |

520 |

977 |

210 |

4.0 |

14 |

125 |

|

|

V6−H−4T250G V6−H−4T280L |

||||||||||

|

V6−H−4T280G V6−H−4T315L |

||||||||||

|

V6−H−4T315G V6−H−4T355L |

810 |

1358 |

425 |

520 |

1300 |

210 |

4.0 |

14 |

215 |

|

|

V6−H−4T355G V6−H−4T400L |

||||||||||

|

400V |

V6−H−4T400G V6−H−4T450L |

810 |

1358 |

425 |

520 |

1300 |

210 |

4.0 |

14 |

215 |

|

V6−H−4T450G V6−H−4T500L |

||||||||||

|

V6−H−4T500G V6−H−4T560L |

||||||||||

Applications

|

|

|

|

|

|

|

|

|

Printing Packaging, Petrochemical, Textile, Cable Machinery, Food Packaging, Electric Vehicles, Plastic Machinery, Metal Products Equipment, Centrifuges and High-end applications requiring closed-loop vector or torque control.

Request for Quotation

Request for Quotation