-

PLC control with well known brand machine parts

-

Durable and stable, quality guaranteed

PLC control with well known brand machine parts

Durable and stable, quality guaranteed

Support Service :

Life-time ServiceTrainning Service :

YesMachine Weight :

8000KGSMachine Dimension :

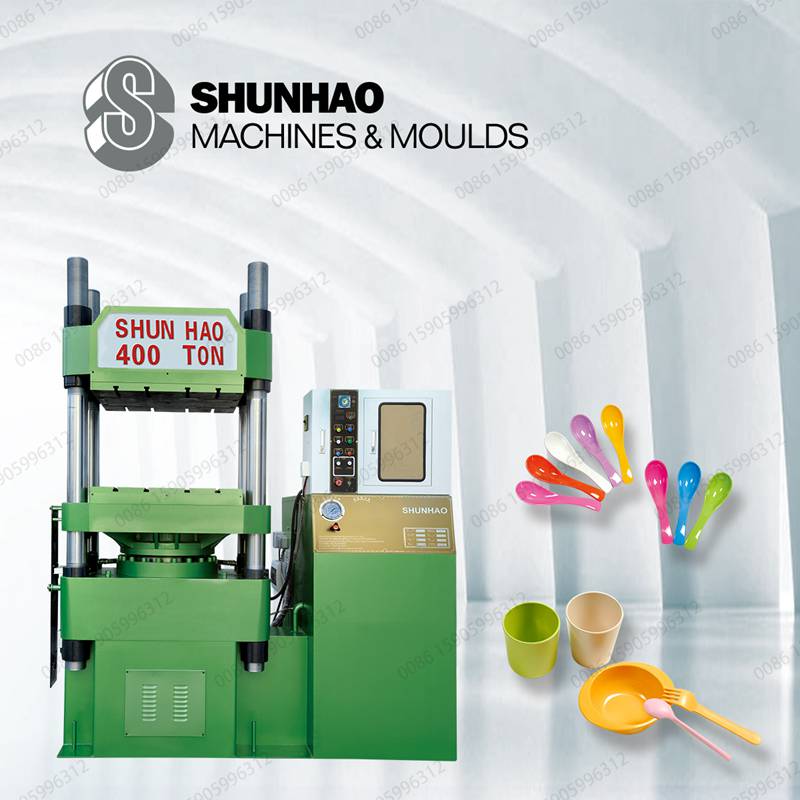

2.5*1.48*2.85 MPLC Control Melamine Crockery Compression Machine

Advantages of Shunhao Machines & Moulds

1. Shunhao Machines & Moulds has been devoted to mechanical production for 18 years

2. Shunhao Machines & Moulds has a professional R&D and production team

3. The machine is PLC control and adopts imported Mitsubishi Electric,touch screen adopts Fuji Electric of Japan

4. The melamine forming machine produced by Shunhao and the toilet lid forming machine have high grinding precision, smooth finished surface, high gloss, beautiful and durable

5. Shunhao products cover:

6. Can customize product functions according to customer requirements, pioneering one operator two machines type.

How to operate and maintain the melamine molding machine correctly and safely?

1. It is forbidden to assist operation by hand when the machine is running.

2. Remember the position of the emergency stop switch.

3. Workers should wear short-sleeved clothes.

4. Turn off the power of the machine before checking the machine.

5. Trouble shooting should be carried out by experts or technicians.

6. Keep the machine and surrounding environment clean.

Technical Parameters

Maximum Working

Pressure

210kg/cm2

2

Main Cylinder

Piston Diameter

Ø500mm

3

Main Cylinder

Working Stroke

550mm

4

Adjustable Table

Distance

500~960mm

5

Heating Plate

Size

900*860mm

6

Working Layers

1 layer

7

Heating Plate

Material

45#

8

Tension Column

(Heat Treatment Grinding)

Ø125*2350mm

9

Oil Hydraulic

Pump

21Mpa

10

Motor

Specifications

15HP

11

Heating Sheet

Total Power

19.6KW

12

Machine Total

Power

30.6KW

1

■ PS: Specifications subject to change without notice.

Request for Quotation

Request for Quotation